Page 21 -

P. 21

10 1 From Optical MEMS to Micromechanical Photonics

absorption rate is proportional to the square of the incident light intensity, a

3-D structure is fabricated by scanningthe focused spot of a near-infrared-

wavelength beam in three dimensions inside the resin. The lateral and depth

resolutions are said to 0.62 and 2.2 µm, respectively. After that, they also

succeeded in fabricatinga micrometer sized cow with a resolution of 140 nm

[1.30].

Replication

Replication from a mold is important technology for realizing lower cost and

mass production. For optical MEMS applications, the use of sol–gels which

become glass-like material upon curing is foreseen. ORMOCER US-S4 is such

a material. It is optically transparent over the wavelength from 400 to 1600 nm

and has a refractive index of 1.52 at 588 nm. Obi et al. replicated many sol–gel

micro-optical devices and optical MEMS includinga sol–gel cantilever with a

microlens on the top [1.31].

1.2.3 Monolithic Integration – Micromachining for an LD

Monolithic integration of micromechanics is possible not only on a Si sub-

strate but also on a semiconductor LD substrate of GaAs [1.14] or InP [1.15].

A smooth etched surface and a deep vertical sidewall are necessary for good

lasingcharacteristics of LDs.

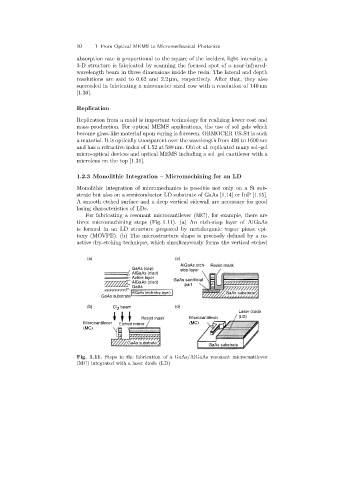

For fabricatinga resonant microcantilever (MC), for example, there are

three micromachiningsteps (Fig. 1.11). (a) An etch-stop layer of AlGaAs

is formed in an LD structure prepared by metalorganic vapor phase epi-

taxy (MOVPE). (b) The microstructure shape is precisely defined by a re-

active dry-etchingtechnique, which simultaneously forms the vertical etched

(a) (c)

AlGaAs etch- Resist mask

GaAs (cap) stop layer

AlGaAs (clad)

Active layer GaAs sacrificial

AlGaAs (clad) part

GaAs

AlGaAs (etch-stop layer) GaAs substrate

GaAs substrate

(b) Cl beam (d)

2

Laser diode

Resist mask Microcantilever (LD)

Microcantilever Etched mirror (MC)

(MC)

GaAs substrate

GaAs substrate

Fig. 1.11. Steps in the fabrication of a GaAs/AlGaAs resonant microcantilever

(MC)integrated with a laser diode (LD)