Page 112 - A Practical Guide from Design Planning to Manufacturing

P. 112

Design Planning 85

Because from scratch designs are only rarely attempted, for most

processor designs the most important design decision is choosing the pre-

vious design on which the new product will be based.

Product Cost

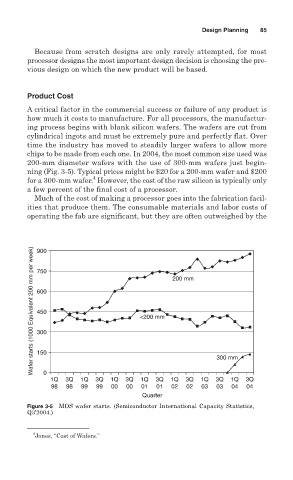

A critical factor in the commercial success or failure of any product is

how much it costs to manufacture. For all processors, the manufactur-

ing process begins with blank silicon wafers. The wafers are cut from

cylindrical ingots and must be extremely pure and perfectly flat. Over

time the industry has moved to steadily larger wafers to allow more

chips to be made from each one. In 2004, the most common size used was

200-mm diameter wafers with the use of 300-mm wafers just begin-

ning (Fig. 3-5). Typical prices might be $20 for a 200-mm wafer and $200

4

for a 300-mm wafer. However, the cost of the raw silicon is typically only

a few percent of the final cost of a processor.

Much of the cost of making a processor goes into the fabrication facil-

ities that produce them. The consumable materials and labor costs of

operating the fab are significant, but they are often outweighed by the

Wafer starts (1000 Equivalent 200 mm per week) 750 <200 mm 200 mm

900

600

450

300

150

300 mm

0

1Q 3Q 1Q 3Q 1Q 3Q 1Q 3Q 1Q 3Q 1Q 3Q 1Q 3Q

98 98 99 99 00 00 01 01 02 02 03 03 04 04

Quarter

Figure 3-5 MOS wafer starts. (Semiconductor International Capacity Statistics,

Q3’2004.)

4

Jones, “Cost of Wafers.”