Page 116 - A Practical Guide from Design Planning to Manufacturing

P. 116

Design Planning 89

5

4

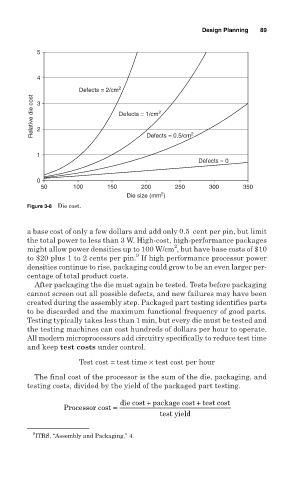

Defects = 2/cm 2

Relative die cost 3 Defects = 1/cm 2 2

2

Defects = 0.5/cm

1

Defects = 0

0

50 100 150 200 250 300 350

2

Die size (mm )

Figure 3-8 Die cost.

a base cost of only a few dollars and add only 0.5 cent per pin, but limit

the total power to less than 3 W. High-cost, high-performance packages

2

might allow power densities up to 100 W/cm , but have base costs of $10

9

to $20 plus 1 to 2 cents per pin. If high performance processor power

densities continue to rise, packaging could grow to be an even larger per-

centage of total product costs.

After packaging the die must again be tested. Tests before packaging

cannot screen out all possible defects, and new failures may have been

created during the assembly step. Packaged part testing identifies parts

to be discarded and the maximum functional frequency of good parts.

Testing typically takes less than 1 min, but every die must be tested and

the testing machines can cost hundreds of dollars per hour to operate.

All modern microprocessors add circuitry specifically to reduce test time

and keep test costs under control.

Test cost = test time × test cost per hour

The final cost of the processor is the sum of the die, packaging, and

testing costs, divided by the yield of the packaged part testing.

+

die cost + package cost test coost

Processor cost =

test yield

9

ITRS, “Assembly and Packaging,” 4.