Page 269 - A Practical Guide from Design Planning to Manufacturing

P. 269

Layout 241

Length

N+

diffusion Length

Poly

gate

Width

Poly

Width S S S S Source e e e Drain

gate

Source Drain

N+

P-well P-well Diffusion

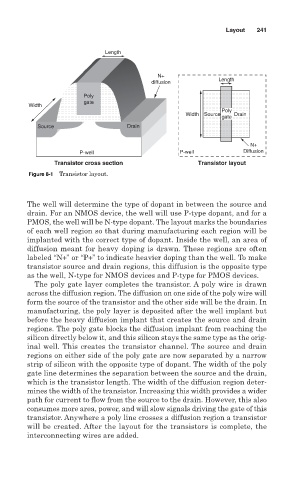

Transistor cross section Transistor layout

Figure 8-1 Transistor layout.

The well will determine the type of dopant in between the source and

drain. For an NMOS device, the well will use P-type dopant, and for a

PMOS, the well will be N-type dopant. The layout marks the boundaries

of each well region so that during manufacturing each region will be

implanted with the correct type of dopant. Inside the well, an area of

diffusion meant for heavy doping is drawn. These regions are often

labeled “N+” or “P+” to indicate heavier doping than the well. To make

transistor source and drain regions, this diffusion is the opposite type

as the well, N-type for NMOS devices and P-type for PMOS devices.

The poly gate layer completes the transistor. A poly wire is drawn

across the diffusion region. The diffusion on one side of the poly wire will

form the source of the transistor and the other side will be the drain. In

manufacturing, the poly layer is deposited after the well implant but

before the heavy diffusion implant that creates the source and drain

regions. The poly gate blocks the diffusion implant from reaching the

silicon directly below it, and this silicon stays the same type as the orig-

inal well. This creates the transistor channel. The source and drain

regions on either side of the poly gate are now separated by a narrow

strip of silicon with the opposite type of dopant. The width of the poly

gate line determines the separation between the source and the drain,

which is the transistor length. The width of the diffusion region deter-

mines the width of the transistor. Increasing this width provides a wider

path for current to flow from the source to the drain. However, this also

consumes more area, power, and will slow signals driving the gate of this

transistor. Anywhere a poly line crosses a diffusion region a transistor

will be created. After the layout for the transistors is complete, the

interconnecting wires are added.