Page 345 - A Practical Guide from Design Planning to Manufacturing

P. 345

Microprocessor Packaging 315

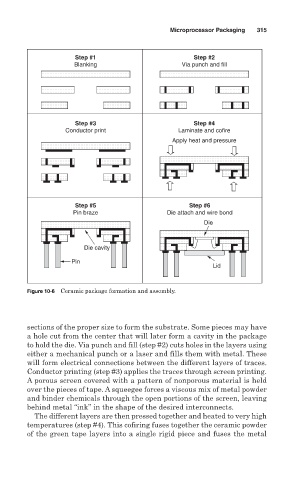

Step #1 Step #2

Blanking Via punch and fill

Step #3 Step #4

Conductor print Laminate and cofire

Apply heat and pressure

Step #5 Step #6

Pin braze Die attach and wire bond

Die

Die cavity

Pin

Lid

Figure 10-6 Ceramic package formation and assembly.

sections of the proper size to form the substrate. Some pieces may have

a hole cut from the center that will later form a cavity in the package

to hold the die. Via punch and fill (step #2) cuts holes in the layers using

either a mechanical punch or a laser and fills them with metal. These

will form electrical connections between the different layers of traces.

Conductor printing (step #3) applies the traces through screen printing.

A porous screen covered with a pattern of nonporous material is held

over the pieces of tape. A squeegee forces a viscous mix of metal powder

and binder chemicals through the open portions of the screen, leaving

behind metal “ink” in the shape of the desired interconnects.

The different layers are then pressed together and heated to very high

temperatures (step #4). This cofiring fuses together the ceramic powder

of the green tape layers into a single rigid piece and fuses the metal