Page 162 - Microsensors, MEMS and Smart Devices - Gardner Varadhan and Awadelkarim

P. 162

142 SILICON MICROMACHINING: BULK

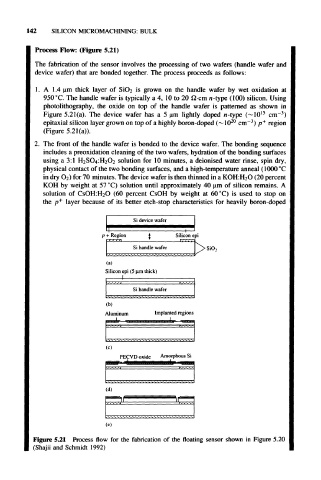

Process Flow: (Figure 5.21)

The fabrication of the sensor involves the processing of two wafers (handle wafer and

device wafer) that are bonded together. The process proceeds as follows:

1. A 1.4 urn thick layer of SiO 2 is grown on the handle wafer by wet oxidation at

950 °C. The handle wafer is typically a 4, 10 to 20 £2-cm n-type (100) silicon. Using

photolithography, the oxide on top of the handle wafer is patterned as shown in

–3

Figure 5.21(a). The device wafer has a 5 urn lightly doped n-type (~10 15 cm )

20

–3

epitaxial silicon layer grown on top of a highly boron-doped (~10 cm ) p + region

(Figure 5.21 (a)).

2. The front of the handle wafer is bonded to the device wafer. The bonding sequence

includes a preoxidation cleaning of the two wafers, hydration of the bonding surfaces

using a 3:1 H 2SO 4:H 2O 2 solution for 10 minutes, a deionised water rinse, spin dry,

physical contact of the two bonding surfaces, and a high-temperature anneal (1000°C

in dry O 2) for 70 minutes. The device wafer is then thinned in a KOH:H 2O (20 percent

KOH by weight at 57 °C) solution until approximately 40 um of silicon remains. A

solution of CsOH:H 2O (60 percent CsOH by weight at 60 °C) is used to stop on

the p + layer because of its better etch-stop characteristics for heavily boron-doped

Si device wafer

p + Region Silicon epi

Si handle wafer

(a)

Silicon epi (5 um thick)

Si handle wafer

(b)

Aluminum Implanted regions

(c)

PECVD oxide Amorphous Si

(d)

(e)

Figure 5.21 Process flow for the fabrication of the floating sensor shown in Figure 5.20

(Shajii and Schmidt 1992)