Page 159 - Microsensors, MEMS and Smart Devices - Gardner Varadhan and Awadelkarim

P. 159

SILICON FUSION BONDING 139

most of the common metals that are used in device fabrication melt below this temperature.

Therefore, to make full use of the potential provided by wafer bonding for microstruc-

tures, low-temperature bonding methods have to be developed. Attempts to lower bonding

temperatures and still achieve reasonable bond strength are currently under way.

Three annealing temperature ranges are of interest in wafer bonding:

1. Temperature less than 450°C for postmetallisation wafers.

2. Temperature less than 800 °C for wafers with diffusion dopant layers (e.g. p + etch-stop

layers).

3. Temperature greater than 1000°C for wafer bonding before processing. According to

the reaction mechanism, annealing at temperatures above 1000°C for several hours

should result in an almost complete reaction of the interface. A 1000 °C anneal for

about two hours gives sufficiently high bond strength for all subsequent treatments

(Harendt et al. 1991); it is not possible to separate the two bonded Si wafers without

breaking the silicon.

An 800 °C anneal results in sufficient bond strength for subsequent processes such as

grinding, polishing, or etching. However, the bonding is incomplete, as suggested by

partial delamination of thinned films after stress treatment (Harendt et al. 1991). The low-

temperature anneal (T < 450 °C) is inadequate for full wafer bonding. Although a signif-

icant increase in bond strength is already measurable after annealing at 200 °C (Kissinger

and Kissinger 1991), additional voids develop during annealing in the temperature range

200 to 700 °C and disappear at higher temperatures. If annealing is interrupted in this

temperature range, these voids remain after cooling; they probably originate from the inter-

facial water, which dissolves and reacts at temperatures above 800 °C. Patterned wafers,

however, have been successfully annealed at 450 °C without the development of additional

voids. In this case, the cavities probably act as buffers for the water. Table 5.4 is taken from

Harendt et al. (1991) and it gives the bond quality for different annealing temperatures.

5.6.3 Fusion of Silicon-Based Materials

Fusion bonding of poly silicon, SiO 2, or silicon nitride to silicon proceeds in a manner

similar to silicon-to-silicon bonding. In the case of polysilicon bonding to silicon, a

polishing step for the two surfaces to be bonded is necessary. This polishing step produces

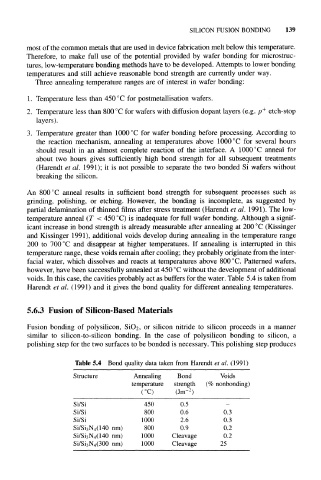

Table 5.4 Bond quality data taken from Harendt et al. (1991)

Structure Annealing Bond Voids

temperature strength (% nonbonding)

–2

( °C) (Jm )

Si/Si 450 0.5 -

Si/Si 800 0.6 0.3

Si/Si 1000 2.6 0.3

Si/Si 3N 4(140 nm) 800 0.9 0.2

Si/Si 3N 4(140 nm) 1000 Cleavage 0.2

Si/Si 3N 4(300 nm) 1000 Cleavage 25