Page 155 - Microsensors, MEMS and Smart Devices - Gardner Varadhan and Awadelkarim

P. 155

Photoresist

Thermal SiO 2

Thermal SiO 2

Si substrate Si substrate

(b)

•••§ Thermal SiO 2 Thermal SiO 2

~U1_T

Si sulostrate

Si substrate

(c) (d)

Photoresist

— Aluminum

Aluminum

Thermal SiO 2

Thermal SiO 2 Si substrate

Si substrate

(0

Photoresist Aluminum

Aluminum

Silicon

Thermal SiO 2

Thermal SiO 2

Si substrate

Si substrate

(g) (h)

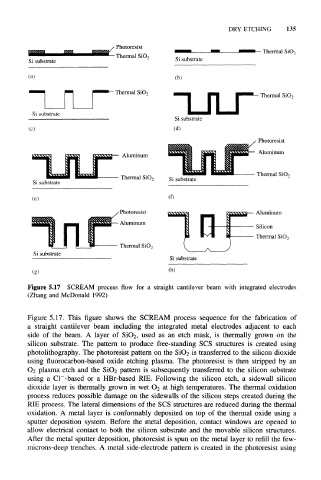

Figure 5.17 SCREAM process flow for a straight cantilever beam with integrated electrodes

(Zhang and McDonald 1992)

Figure 5.17. This figure shows the SCREAM process sequence for the fabrication of

a straight cantilever beam including the integrated metal electrodes adjacent to each

side of the beam. A layer of SiO 2, used as an etch mask, is thermally grown on the

silicon substrate. The pattern to produce free-standing SCS structures is created using

photolithography. The photoresist pattern on the SiO 2 is transferred to the silicon dioxide

using fluorocarbon-based oxide etching plasma. The photoresist is then stripped by an

O2 plasma etch and the SiO 2 pattern is subsequently transferred to the silicon substrate

using a Cl – -based or a HBr-based RIE. Following the silicon etch, a sidewall silicon

dioxide layer is thermally grown in wet O 2 at high temperatures. The thermal oxidation

process reduces possible damage on the sidewalls of the silicon steps created during the

RIE process. The lateral dimensions of the SCS structures are reduced during the thermal

oxidation. A metal layer is conformably deposited on top of the thermal oxide using a

sputter deposition system. Before the metal deposition, contact windows are opened to

allow electrical contact to both the silicon substrate and the movable silicon structures.

After the metal sputter deposition, photoresist is spun on the metal layer to refill the few-

microns-deep trenches. A metal side-electrode pattern is created in the photoresist using