Page 154 - Microsensors, MEMS and Smart Devices - Gardner Varadhan and Awadelkarim

P. 154

134 SILICON MICROMACHINING: BULK

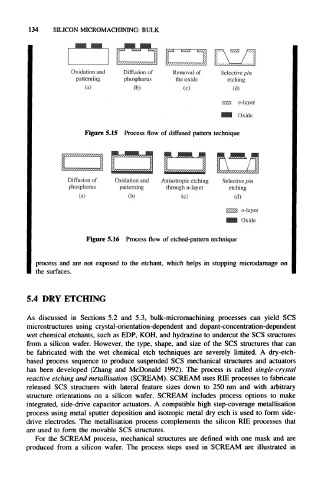

Oxidation and Diffusion of Removal of Selective p/n

patterning phosphorus the oxide etching

(a) (b) (c) (d)

tzza n-layer

•I Oxide

Figure 5.15 Process flow of diffused pattern technique

m jjjjjj^ m

\

Diffusion of Oxidation and Anisotropic etchin Selective p/n

phosphorus patterning through n-layer etching

(a) (b) (c) (d)

V777A n-layer

^H Oxide

Figure 5.16 Process flow of etched-pattern technique

process and are not exposed to the etchant, which helps in stopping microdamage on

the surfaces.

5.4 DRY ETCHING

As discussed in Sections 5.2 and 5.3, bulk-micromachining processes can yield SCS

microstructures using crystal-orientation-dependent and dopant-concentration-dependent

wet chemical etchants, such as EDP, KOH, and hydrazine to undercut the SCS structures

from a silicon wafer. However, the type, shape, and size of the SCS structures that can

be fabricated with the wet chemical etch techniques are severely limited. A dry-etch-

based process sequence to produce suspended SCS mechanical structures and actuators

has been developed (Zhang and McDonald 1992). The process is called single-crystal

reactive etching and metallisation (SCREAM). SCREAM uses RIE processes to fabricate

released SCS structures with lateral feature sizes down to 250 nm and with arbitrary

structure orientations on a silicon wafer. SCREAM includes process options to make

integrated, side-drive capacitor actuators. A compatible high step-coverage metallisation

process using metal sputter deposition and isotropic metal dry etch is used to form side-

drive electrodes. The metallisation process complements the silicon RIE processes that

are used to form the movable SCS structures.

For the SCREAM process, mechanical structures are defined with one mask and are

produced from a silicon wafer. The process steps used in SCREAM are illustrated in