Page 150 - Microsensors, MEMS and Smart Devices - Gardner Varadhan and Awadelkarim

P. 150

130 SILICON MICROMACHINING: BULK

Op-amp

u I •

06

o 0.4 "

f_\

1

on

» c u.u

.c

Kb

i

|» -0.4 - Va

3

-0.8 - h ™ -

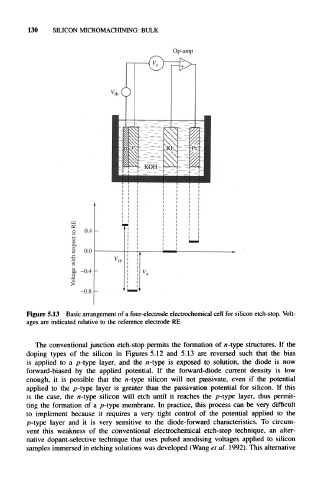

Figure 5.13 Basic arrangement of a four-electrode electrochemical cell for silicon etch-stop. Volt-

ages are indicated relative to the reference electrode RE

The conventional junction etch-stop permits the formation of n-type structures. If the

doping types of the silicon in Figures 5.12 and 5.13 are reversed such that the bias

is applied to a p-type layer, and the n-type is exposed to solution, the diode is now

forward-biased by the applied potential. If the forward-diode current density is low

enough, it is possible that the n-type silicon will not passivate, even if the potential

applied to the p-type layer is greater than the passivation potential for silicon. If this

is the case, the n-type silicon will etch until it reaches the p-type layer, thus permit-

ting the formation of a p-type membrane. In practice, this process can be very difficult

to implement because it requires a very tight control of the potential applied to the

p-type layer and it is very sensitive to the diode-forward characteristics. To circum-

vent this weakness of the conventional electrochemical etch-stop technique, an alter-

native dopant-selective technique that uses pulsed anodising voltages applied to silicon

samples immersed in etching solutions was developed (Wang et al. 1992). This alternative