Page 242 - Microsensors, MEMS and Smart Devices - Gardner Varadhan and Awadelkarim

P. 242

222 MICROSTEREOLITHOGRAPHY FOR MEMS

because thermal pneumatic actuation was adopted, which may not be acceptable in some

applications requiring high flow uniformity. The technical data of this type of micropump

are listed in Table 7.1. It should be noted that both the housings and the diaphragms of the

micropump are made of polymer and can be selected according to the special demands of

the particular application, for example, biomedical fluid delivery. Another advantage of

AMANDA is that it is a batch-fabrication process and therefore enables the production

of a micropump at a relatively low cost.

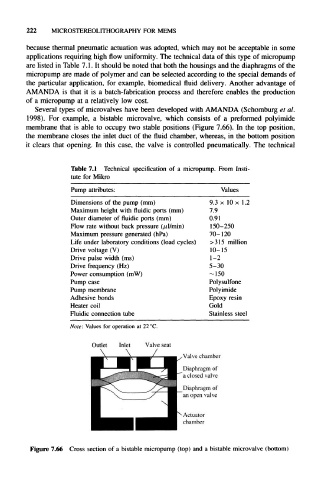

Several types of microvalves have been developed with AMANDA (Schomburg et al.

1998). For example, a bistable microvalve, which consists of a preformed polyimide

membrane that is able to occupy two stable positions (Figure 7.66). In the top position,

the membrane closes the inlet duct of the fluid chamber, whereas, in the bottom position

it clears that opening. In this case, the valve is controlled pneumatically. The technical

Table 7.1 Technical specification of a micropump. From Insti-

tute for Mikro

Pump attributes: Values

Dimensions of the pump (mm) 9.3 x 10 x 1.2

Maximum height with fluidic ports (mm) 7.9

Outer diameter of fluidic ports (mm) 0.91

Flow rate without back pressure (^il/min) 150-250

Maximum pressure generated (hPa) 70–120

Life under laboratory conditions (load cycles) >315 million

Drive voltage (V) 10-15

Drive pulse width (ms) 1–2

Drive frequency (Hz) 5-30

Power consumption (mW) ~ 150

Pump case Polysulfone

Pump membrane Polyimide

Adhesive bonds Epoxy resin

Heater coil Gold

Fluidic connection tube Stainless steel

Note: Values for operation at 22 °C.

Figure 7.66 Cross section of a bistable micropump (top) and a bistable microvalve (bottom)