Page 244 - Microsensors, MEMS and Smart Devices - Gardner Varadhan and Awadelkarim

P. 244

224 MICROSTEREOLITHOGRAPHY FOR MEMS

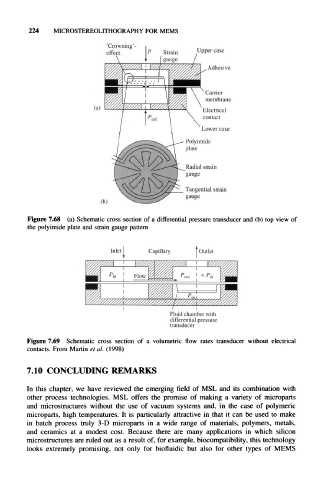

Figure 7.68 (a) Schematic cross section of a differential pressure transducer and (b) top view of

the polyimide plate and strain gauge pattern

Figure 7.69 Schematic cross section of a volumetric flow rates transducer without electrical

contacts. From Martin et al. (1998)

7.10 CONCLUDING REMARKS

In this chapter, we have reviewed the emerging field of MSL and its combination with

other process technologies. MSL offers the promise of making a variety of microparts

and microstructures without the use of vacuum systems and, in the case of polymeric

microparts, high temperatures. It is particularly attractive in that it can be used to make

in batch process truly 3-D microparts in a wide range of materials, polymers, metals,

and ceramics at a modest cost. Because there are many applications in which silicon

microstructures are ruled out as a result of, for example, biocompatibility, this technology

looks extremely promising, not only for biofluidic but also for other types of MEMS