Page 240 - Microsensors, MEMS and Smart Devices - Gardner Varadhan and Awadelkarim

P. 240

220 MICROSTEREOLITHOGRAPHY FOR MEMS

Figure 7.62 Long-exposure photograph to show the luminescence from the concentrator during

reagent supply. From Ikuta et al. (1999)

300-

400

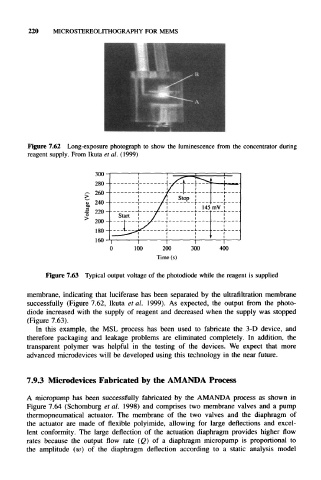

Figure 7.63 Typical output voltage of the photodiode while the reagent is supplied

membrane, indicating that luciferase has been separated by the ultrafiltration membrane

successfully (Figure 7.62, Ikuta et al. 1999). As expected, the output from the photo-

diode increased with the supply of reagent and decreased when the supply was stopped

(Figure 7.63).

In this example, the MSL process has been used to fabricate the 3-D device, and

therefore packaging and leakage problems are eliminated completely. In addition, the

transparent polymer was helpful in the testing of the devices. We expect that more

advanced microdevices will be developed using this technology in the near future.

7.9.3 Microdevices Fabricated by the AMANDA Process

A micropump has been successfully fabricated by the AMANDA process as shown in

Figure 7.64 (Schomburg et al. 1998) and comprises two membrane valves and a pump

thermopneumatical actuator. The membrane of the two valves and the diaphragm of

the actuator are made of flexible polyimide, allowing for large deflections and excel-

lent conformity. The large deflection of the actuation diaphragm provides higher flow

rates because the output flow rate (Q) of a diaphragm micropump is proportional to

the amplitude (w) of the diaphragm deflection according to a static analysis model