Page 235 - Microsensors, MEMS and Smart Devices - Gardner Varadhan and Awadelkarim

P. 235

COMBINED SILICON AND POLYMERIC STRUCTURES 215

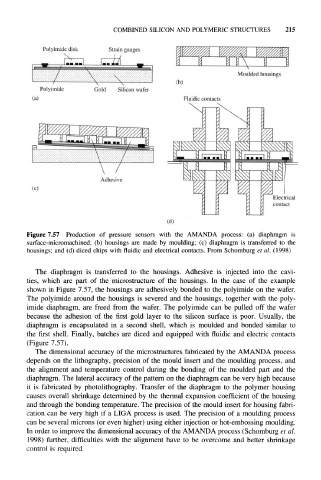

Figure 7.57 Production of pressure sensors with the AMANDA process: (a) diaphragm is

surface-micromachined; (b) housings are made by moulding; (c) diaphragm is transferred to the

housings; and (d) diced chips with fluidic and electrical contacts. From Schomburg et al. (1998)

The diaphragm is transferred to the housings. Adhesive is injected into the cavi-

ties, which are part of the microstructure of the housings. In the case of the example

shown in Figure 7.57, the housings are adhesively bonded to the polyimide on the wafer.

The polyimide around the housings is severed and the housings, together with the poly-

imide diaphragm, are freed from the wafer. The polyimide can be pulled off the wafer

because the adhesion of the first gold layer to the silicon surface is poor. Usually, the

diaphragm is encapsulated in a second shell, which is moulded and bonded similar to

the first shell. Finally, batches are diced and equipped with fluidic and electric contacts

(Figure 7.57).

The dimensional accuracy of the microstructures fabricated by the AMANDA process

depends on the lithography, precision of the mould insert and the moulding process, and

the alignment and temperature control during the bonding of the moulded part and the

diaphragm. The lateral accuracy of the pattern on the diaphragm can be very high because

it is fabricated by photolithography. Transfer of the diaphragm to the polymer housing

causes overall shrinkage determined by the thermal expansion coefficient of the housing

and through the bonding temperature. The precision of the mould insert for housing fabri-

cation can be very high if a LIGA process is used. The precision of a moulding process

can be several microns (or even higher) using either injection or hot-embossing moulding.

In order to improve the dimensional accuracy of the AMANDA process (Schomburg et al.

1998) further, difficulties with the alignment have to be overcome and better shrinkage

control is required.