Page 232 - Microsensors, MEMS and Smart Devices - Gardner Varadhan and Awadelkarim

P. 232

212 MICROSTEREOLITHOGRAPHY FOR MEMS

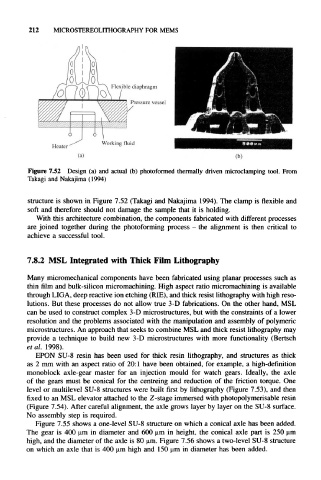

Figure 7.52 Design (a) and actual (b) photoformed thermally driven microclamping tool. From

Takagi and Nakajima (1994)

structure is shown in Figure 7.52 (Takagi and Nakajima 1994). The clamp is flexible and

soft and therefore should not damage the sample that it is holding.

With this architecture combination, the components fabricated with different processes

are joined together during the photoforming process - the alignment is then critical to

achieve a successful tool.

7.8.2 MSL Integrated with Thick Film Lithography

Many micromechanical components have been fabricated using planar processes such as

thin film and bulk-silicon micromachining. High aspect ratio micromachining is available

through LIGA, deep reactive ion etching (RIE), and thick resist lithography with high reso-

lutions. But these processes do not allow true 3-D fabrications. On the other hand, MSL

can be used to construct complex 3-D microstructures, but with the constraints of a lower

resolution and the problems associated with the manipulation and assembly of polymeric

microstructures. An approach that seeks to combine MSL and thick resist lithography may

provide a technique to build new 3-D microstructures with more functionality (Bertsch

et al. 1998).

EPON SU-8 resin has been used for thick resin lithography, and structures as thick

as 2 mm with an aspect ratio of 20:1 have been obtained, for example, a high-definition

monoblock axle-gear master for an injection mould for watch gears. Ideally, the axle

of the gears must be conical for the centreing and reduction of the friction torque. One

level or multilevel SU-8 structures were built first by lithography (Figure 7.53), and then

fixed to an MSL elevator attached to the Z-stage immersed with photopolymerisable resin

(Figure 7.54). After careful alignment, the axle grows layer by layer on the SU-8 surface.

No assembly step is required.

Figure 7.55 shows a one-level SU-8 structure on which a conical axle has been added.

The gear is 400 urn in diameter and 600 urn in height, the conical axle part is 250 urn

high, and the diameter of the axle is 80 urn. Figure 7.56 shows a two-level SU-8 structure

on which an axle that is 400 urn high and 150 urn in diameter has been added.