Page 236 - Microsensors, MEMS and Smart Devices - Gardner Varadhan and Awadelkarim

P. 236

216 MICROSTEREOLITHOGRAPHY FOR MEMS

7.9 APPLICATIONS

Various microdevices have been developed to date using the microfabrication processes

described earlier. This section describes the fabrication of some microsensors and microac-

tuators using the MSL and the AMANDA processes.

7.9.1 Microactuators Fabricated by MSL

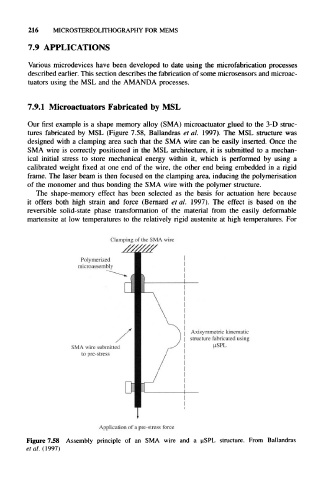

Our first example is a shape memory alloy (SMA) microactuator glued to the 3-D struc-

tures fabricated by MSL (Figure 7.58, Ballandras et al 1997). The MSL structure was

designed with a clamping area such that the SMA wire can be easily inserted. Once the

SMA wire is correctly positioned in the MSL architecture, it is submitted to a mechan-

ical initial stress to store mechanical energy within it, which is performed by using a

calibrated weight fixed at one end of the wire, the other end being embedded in a rigid

frame. The laser beam is then focused on the clamping area, inducing the polymerisation

of the monomer and thus bonding the SMA wire with the polymer structure.

The shape-memory effect has been selected as the basis for actuation here because

it offers both high strain and force (Bernard et al. 1997). The effect is based on the

reversible solid-state phase transformation of the material from the easily deformable

martensite at low temperatures to the relatively rigid austenite at high temperatures. For

Figure 7.58 Assembly principle of an SMA wire and a nSPL structure. From Ballandras

etal. (1997)