Page 229 - Microsensors, MEMS and Smart Devices - Gardner Varadhan and Awadelkarim

P. 229

POLYMERIC MEMS ARCHITECTURE 209

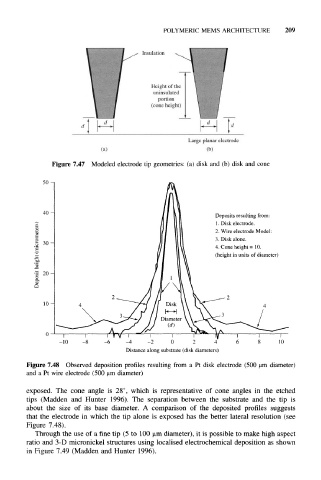

Figure 7.47 Modeled electrode tip geometries: (a) disk and (b) disk and cone

50 -i

Deposits resulting from:

1. Disk electrode.

2. Wire electrode Model:

3. Disk alone.

4. Cone height = 10.

(height in units of diameter)

-10 -4 -2 0

Distance along substrate (disk diameters)

Figure 7.48 Observed deposition profiles resulting from a Pt disk electrode (500 diameter)

and a Pt wire electrode (500 urn diameter)

exposed. The cone angle is 28°, which is representative of cone angles in the etched

tips (Madden and Hunter 1996). The separation between the substrate and the tip is

about the size of its base diameter. A comparison of the deposited profiles suggests

that the electrode in which the tip alone is exposed has the better lateral resolution (see

Figure 7.48).

Through the use of a fine tip (5 to 100 um diameter), it is possible to make high aspect

ratio and 3-D micronickel structures using localised electrochemical deposition as shown

in Figure 7.49 (Madden and Hunter 1996).