Page 226 - Microsensors, MEMS and Smart Devices - Gardner Varadhan and Awadelkarim

P. 226

206 MICROSTEREOLITHOGRAPHY FOR MEMS

Metal

(Part 1)

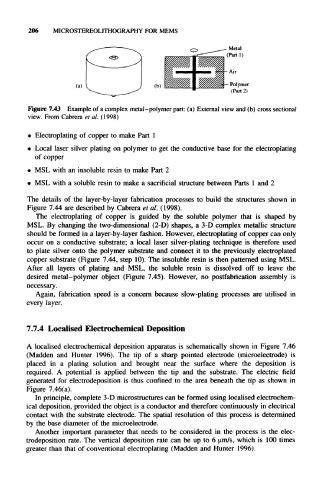

Figure 7.43 Example of a complex metal-polymer part: (a) External view and (b) cross sectional

view. From Cabrera et al. (1998)

• Electroplating of copper to make Part 1

• Local laser silver plating on polymer to get the conductive base for the electroplating

of copper

• MSL with an insoluble resin to make Part 2

• MSL with a soluble resin to make a sacrificial structure between Parts 1 and 2

The details of the layer-by-layer fabrication processes to build the structures shown in

Figure 7.44 are described by Cabrera et al. (1998).

The electroplating of copper is guided by the soluble polymer that is shaped by

MSL. By changing the two-dimensional (2-D) shapes, a 3-D complex metallic structure

should be formed in a layer-by-layer fashion. However, electroplating of copper can only

occur on a conductive substrate; a local laser silver-plating technique is therefore used

to plate silver onto the polymer substrate and connect it to the previously electroplated

copper substrate (Figure 7.44, step 10). The insoluble resin is then patterned using MSL.

After all layers of plating and MSL, the soluble resin is dissolved off to leave the

desired metal-polymer object (Figure 7.45). However, no postfabrication assembly is

necessary.

Again, fabrication speed is a concern because slow-plating processes are utilised in

every layer.

7.7.4 Localised Electrochemical Deposition

A localised electrochemical deposition apparatus is schematically shown in Figure 7.46

(Madden and Hunter 1996). The tip of a sharp pointed electrode (microelectrode) is

placed in a plating solution and brought near the surface where the deposition is

required. A potential is applied between the tip and the substrate. The electric field

generated for electrodeposition is thus confined to the area beneath the tip as shown in

Figure 7.46(a).

In principle, complete 3-D microstructures can be formed using localised electrochem-

ical deposition, provided the object is a conductor and therefore continuously in electrical

contact with the substrate electrode. The spatial resolution of this process is determined

by the base diameter of the microelectrode.

Another important parameter that needs to be considered in the process is the elec-

trodeposition rate. The vertical deposition rate can be up to 6 um/s, which is 100 times

greater than that of conventional electroplating (Madden and Hunter 1996).