Page 223 - Microsensors, MEMS and Smart Devices - Gardner Varadhan and Awadelkarim

P. 223

203

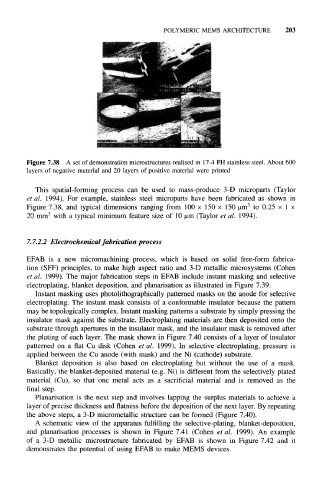

Figure 7.38 A set of demonstration microstructures realised in 17–4 PH stainless steel. About 600

layers of negative material and 20 layers of positive material were printed

This spatial-forming process can be used to mass-produce 3-D microparts (Taylor

et al. 1994). For example, stainless steel microparts have been fabricated as shown in

Figure 7.38, and typical dimensions ranging from 100 x 150 x 150 um 3 to 0.25 x 1 x

20 mm 3 with a typical minimum feature size of 10 urn (Taylor et al. 1994).

7.7.2.2 Electrochemical fabrication process

EFAB is a new micromachining process, which is based on solid free-form fabrica-

tion (SFF) principles, to make high aspect ratio and 3-D metallic microsystems (Cohen

et al. 1999). The major fabrication steps in EFAB include instant masking and selective

electroplating, blanket deposition, and planarisation as illustrated in Figure 7.39.

Instant masking uses photolithographically patterned masks on the anode for selective

electroplating. The instant mask consists of a conformable insulator because the pattern

may be topologically complex. Instant masking patterns a substrate by simply pressing the

insulator mask against the substrate. Electroplating materials are then deposited onto the

substrate through apertures in the insulator mask, and the insulator mask is removed after

the plating of each layer. The mask shown in Figure 7.40 consists of a layer of insulator

patterned on a flat Cu disk (Cohen et al. 1999). In selective electroplating, pressure is

applied between the Cu anode (with mask) and the Ni (cathode) substrate.

Blanket deposition is also based on electroplating but without the use of a mask.

Basically, the blanket-deposited material (e.g. Ni) is different from the selectively plated

material (Cu), so that one metal acts as a sacrificial material and is removed as the

final step.

Planarisation is the next step and involves lapping the surplus materials to achieve a

layer of precise thickness and flatness before the deposition of the next layer. By repeating

the above steps, a 3-D micrometallic structure can be formed (Figure 7.40).

A schematic view of the apparatus fulfilling the selective-plating, blanket-deposition,

and planarisation processes is shown in Figure 7.41 (Cohen et al. 1999). An example

of a 3-D metallic microstructure fabricated by EFAB is shown in Figure 7.42 and it

demonstrates the potential of using EFAB to make MEMS devices.