Page 267 - Microsensors, MEMS and Smart Devices - Gardner Varadhan and Awadelkarim

P. 267

MECHANICAL SENSORS 247

detect low-energy microwave signals with a suitable design of the loop. The signal can

then be used, for example, to generate a SAW in a piezoelectric material for a wireless

mechanical sensor or simply to sense the electrical signal and pass it onto a decoder

(Figure 8.18).

As the microstrip can be made of aluminum, it is compatible with standard microtech-

nology and can be deposited along with the aluminum interconnects. However, the

microantenna can also be used as a transmitter, in which case it is acting as a radiation

microactuator.

The use of microantennae in SAW-IDT microsensors is described in Chapter 13 and

again in the concept of a smart electronic tongue in Chapter 15.

The way in which a machine interfaces with a person is important and is likely to

be a key issue in the future when microsensors and MEMS devices become smaller and

more autonomous. Therefore, the integrated microwave antenna may prove to be a very

useful tool in which a human operator can communicate with and remotely control a

small MEMS structure implanted in some inaccessible environment, such as inside the

human body!

8.4 MECHANICAL SENSORS

8.4.1 Overview

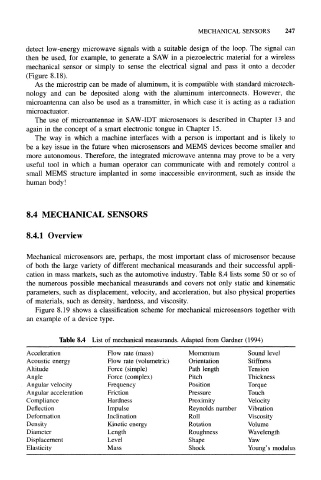

Mechanical microsensors are, perhaps, the most important class of microsensor because

of both the large variety of different mechanical measurands and their successful appli-

cation in mass markets, such as the automotive industry. Table 8.4 lists some 50 or so of

the numerous possible mechanical measurands and covers not only static and kinematic

parameters, such as displacement, velocity, and acceleration, but also physical properties

of materials, such as density, hardness, and viscosity.

Figure 8.19 shows a classification scheme for mechanical microsensors together with

an example of a device type.

Table 8.4 List of mechanical measurands. Adapted from Gardner (1994)

Acceleration Flow rate (mass) Momentum Sound level

Acoustic energy Flow rate (volumetric) Orientation Stiffness

Altitude Force (simple) Path length Tension

Angle Force (complex) Pitch Thickness

Angular velocity Frequency Position Torque

Angular acceleration Friction Pressure Touch

Compliance Hardness Proximity Velocity

Deflection Impulse Reynolds number Vibration

Deformation Inclination Roll Viscosity

Density Kinetic energy Rotation Volume

Diameter Length Roughness Wavelength

Displacement Level Shape Yaw

Elasticity Mass Shock Young's modulus