Page 319 - Microsensors, MEMS and Smart Devices - Gardner Varadhan and Awadelkarim

P. 319

BIO(CHEMICAL) SENSORS 299

Table 8.18 Relative characteristics of the gas microsensors

Sensing Transducer Sensitivity Power/operating Unit CMOS-

material temp. (°C) cost compatible

or not?

Metal oxide (best for Resistive High High/300 High SOI only

combustible gases) with

on-chip

anneal

Conducting polymers QCM High All very Medium No

(best for polar low/ambient

VOCs)

Resistive Medium Low Yes

MOSFET Medium Low Yes

Calorimeter Low High Yes, with

silicon

etch

Catalytic metals (best MOSFET Low Medium/200 Low Yes, with

for reactive gases) etch

Pellistor Low High/500 High No

Solvating polymer SAW High All very Medium Nonstandard

coatings low/ambient

(best for nonpolar QCM High Medium No

VOCs)

Capacitive Medium Low Yes

Resist Medium Low Yes

Calorimetric Low Medium Yes, with

etch

Cantilever Low High Yes, with

etch

The power consumption of the device, shown in Figure 8.64(d), is about 150 mW at

an operating temperature of 450 °C. The microheater has an active area of 570 u,m

square.

27

The catalyst-coated bead was formed electrochemically using a lyotropic self-

assembling material as a template (Attard et al. 1997). The resulting structure is made

up of a regular array of 5.5-nm pores in palladium and has a very high surface area,

2

approximately 1000 m /g (Figure 8.65 (a,b)). Preliminary results of the micropellistor

are shown in Figure 8.65(c). Its response to 2.5 percent methane in air (Lee et al.

2000) suggests that commercial silicon micropellistors may become available in the near

future.

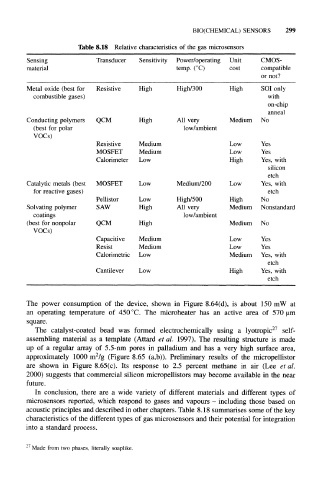

In conclusion, there are a wide variety of different materials and different types of

microsensors reported, which respond to gases and vapours - including those based on

acoustic principles and described in other chapters. Table 8.18 summarises some of the key

characteristics of the different types of gas microsensors and their potential for integration

into a standard process.

27

Made from two phases, literally soaplike.