Page 316 - Microsensors, MEMS and Smart Devices - Gardner Varadhan and Awadelkarim

P. 316

296 MICROSENSORS

disposable single-shot sensing element - the enzyme is coupled to a conducting polymer

in an electrochemical cell. The sensing strips are fabricated using screen printing, rather

than silicon microtechnology, and sold in their millions by companies such as Medisense

(UK). Other coatings can be used to detect lipids, peptides, and so on, but to date, their

commercial success has been somewhat limited by either the long-term stability of the

electrode or the selectivity of the biological coatings.

Finally, there is considerable need in the automotive industry for gas sensors that

can monitor the engine combustion process either in-line or at-line — this is extremely

demanding and rules out conventional CMOS devices that operate only up to a temperature

of about +125°C. However, there is a field-effect diode made from SiC that can be

operated at more than 700 °C and responds in milliseconds (Svenningstorp et al. 2000,

2001). Figure 8.62 shows the response of a MISiC Schottky diode to the exhaust gases

from a car engine (Savage et al. 2000). This device enables the real-time monitoring of

the combustion process in each cylinder as it fires in turn and could well be used as a

diagnostic sensor.

8.6.3 Others

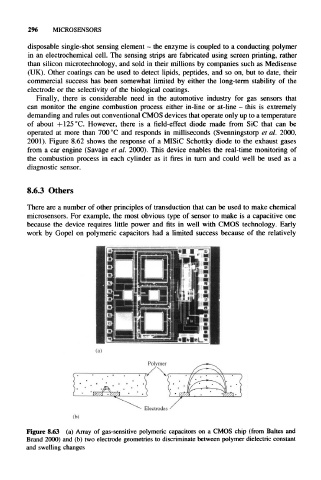

There are a number of other principles of transduction that can be used to make chemical

microsensors. For example, the most obvious type of sensor to make is a capacitive one

because the device requires little power and fits in well with CMOS technology. Early

work by Gopel on polymeric capacitors had a limited success because of the relatively

Figure 8.63 (a) Array of gas-sensitive polymeric capacitors on a CMOS chip (from Baltes and

Brand 2000) and (b) two electrode geometries to discriminate between polymer dielectric constant

and swelling changes