Page 318 - Microsensors, MEMS and Smart Devices - Gardner Varadhan and Awadelkarim

P. 318

298 MICROSENSORS

capacitor with the wide electrodes will measure the entire swelling that is taking place.

Therefore, the selectivity of the capacitive gas microsensor is enhanced.

There is also potential in the development of microcalorimetric gas sensors. For

example, conventional pellistors are made in large quantities to detect the presence of

combustible gases, such as methane in air (Figure 8.64(a)). They work by sensing a

change in temperature of a small catalyst-coated bead held at around 450 °C via a plat-

inum heater or temperature sensing coil. There have been efforts to make a silicon planar

pellistor (Gall 1991) but the demands on the silicon technology are considerable because of

their very high operating temperatures of around 500 °C. However, recent improvements

in microhotplate technology have led to stable operating temperatures of 600 °C, and

combined with novel nanoporous gas-sensitive membranes pioneered by Southampton

University (Lee et al. 2000), Figure 8.64 shows both (b) a schematic cross section of

a silicon micromachined microcalorimeter (micropellistor) and (c) a photograph of the

actual device. The heater can be seen faintly below the solid gold electrode with a

single pad (left) used to electrochemically coat with a nanoporous film of palladium.

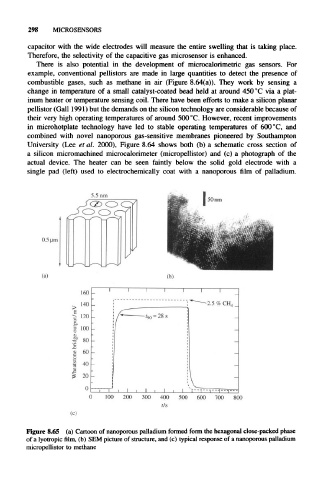

Figure 8.65 (a) Cartoon of nanoporous palladium formed form the hexagonal close-packed phase

of a lyotropic film, (b) SEM picture of structure, and (c) typical response of a nanoporous palladium

micropellistor to methane