Page 359 - Microsensors, MEMS and Smart Devices - Gardner Varadhan and Awadelkarim

P. 359

ANALOGUE (AMPLITUDE) MEASURING SYSTEM 339

1. Far too time-consuming

2. Restricted, as only one acoustic sensor can be measured at a time

3. Allows only steady state measurements; no dynamic response measurements are

possible

4. Very expensive to operate, in terms of both the instrument price and the need for highly

qualified personnel

5. Unable to offer remote-sensing

6. Too cumbersome and not portable

Nevertheless, there are instances in which it is useful to use a network analyser to under-

stand an IDT-SAW problem. For example, most of the work described here on the device

referred to previously as an ice microsensor has been more of a characterisation study,

so it is sensible to employ a network analyser in order to measure the relevant phase

3

difference parameters . This is despite the fact that the network analyser carries with it

all the relevant disadvantages just listed.

Before choosing the configuration to employ, the following question should always be

asked:

'What is the most practical and appropriate form of instrumentation or system to be used

for measuring and analyzing acoustic-based microsensors?'

Wohltjen and Dessy (1979) answered the question by describing three general methods

for measuring the response of a SAW microsensor - amplitude, phase, or frequency

measurements. The following three sections provide typical examples of such measuring

systems (Wohltjen and Dessy 1979) based on these methods.

11.4 ANALOGUE (AMPLITUDE) MEASURING SYSTEM

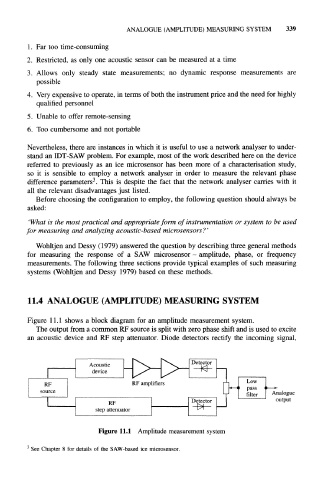

Figure 11.1 shows a block diagram for an amplitude measurement system.

The output from a common RF source is split with zero phase shift and is used to excite

an acoustic device and RF step attenuator. Diode detectors rectify the incoming signal,

Acoustic

device

RF RF amplifiers

source LJ Analogue

RF Detector output

step attenuator

Figure 11.1 Amplitude measurement system

3

See Chapter 8 for details of the SAW-based ice microsensor.