Page 398 - Microsensors, MEMS and Smart Devices - Gardner Varadhan and Awadelkarim

P. 398

378 IDT MICROSENSORS

From preliminary measurements of humidity, it is seen that

— = 3.05 x 10 –6 x RH(%) (13.59)

Although the change in velocity is small, we can replace v 1 in the denominator of the

last term in Equation (13.58) by u 0. Then, using Equations (13.56), (13.58), and (13.59)

we have

–6

x 10 (13.60)

6

Using a frequency of 905 MHz (i.e. W 0 = In x 905 x 10 rad/s), the above

value (1.40 us) for TO, and by converting from radians to degrees, we get

= 1.39 x RH(%) in degrees (13.61)

Therefore, because the wireless system has a phase difference measurement resolution of

1°, this system should provide a resolution of 0.72 percent RH for measurements.

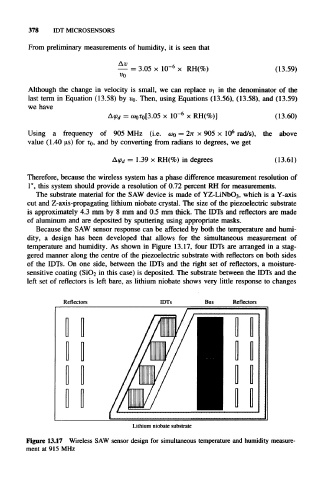

The substrate material for the SAW device is made of YZ-LiNbO 3, which is a Y-axis

cut and Z-axis-propagating lithium niobate crystal. The size of the piezoelectric substrate

is approximately 4.3 mm by 8 mm and 0.5 mm thick. The IDTs and reflectors are made

of aluminum and are deposited by sputtering using appropriate masks.

Because the SAW sensor response can be affected by both the temperature and humi-

dity, a design has been developed that allows for the simultaneous measurement of

temperature and humidity. As shown in Figure 13.17, four IDTs are arranged in a stag-

gered manner along the centre of the piezoelectric substrate with reflectors on both sides

of the IDTs. On one side, between the IDTs and the right set of reflectors, a moisture-

sensitive coating (SiO 2 in this case) is deposited. The substrate between the IDTs and the

left set of reflectors is left bare, as lithium niobate shows very little response to changes

Reflectors IDTs Bus Reflectors

Lithium niobate substrate

Figure 13.17 Wireless SAW sensor design for simultaneous temperature and humidity measure-

ment at 915 MHz