Page 402 - Microsensors, MEMS and Smart Devices - Gardner Varadhan and Awadelkarim

P. 402

382 IDT MICROSENSORS

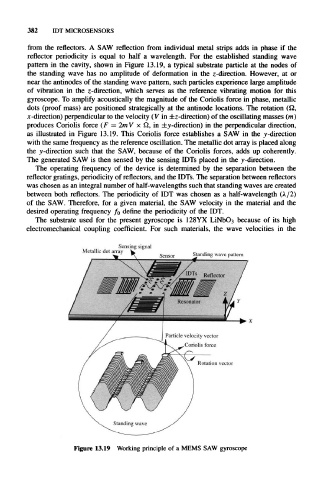

from the reflectors. A SAW reflection from individual metal strips adds in phase if the

reflector periodicity is equal to half a wavelength. For the established standing wave

pattern in the cavity, shown in Figure 13.19, a typical substrate particle at the nodes of

the standing wave has no amplitude of deformation in the z-direction. However, at or

near the antinodes of the standing wave pattern, such particles experience large amplitude

of vibration in the z-direction, which serves as the reference vibrating motion for this

gyroscope. To amplify acoustically the magnitude of the Coriolis force in phase, metallic

dots (proof mass) are positioned strategically at the antinode locations. The rotation (ft,

x-direction) perpendicular to the velocity (V in ±z-direction) of the oscillating masses (m)

produces Coriolis force (F = 2m V x ft, in +y-direction) in the perpendicular direction,

as illustrated in Figure 13.19. This Coriolis force establishes a SAW in the y-direction

with the same frequency as the reference oscillation. The metallic dot array is placed along

the j-direction such that the SAW, because of the Coriolis forces, adds up coherently.

The generated SAW is then sensed by the sensing IDTs placed in the v-direction.

The operating frequency of the device is determined by the separation between the

reflector gratings, periodicity of reflectors, and the IDTs. The separation between reflectors

was chosen as an integral number of half-wavelengths such that standing waves are created

between both reflectors. The periodicity of IDT was chosen as a half-wavelength (A./2)

of the SAW. Therefore, for a given material, the SAW velocity in the material and the

desired operating frequency f 0 define the periodicity of the IDT.

The substrate used for the present gyroscope is 128YX LiNbO 3 because of its high

electromechanical coupling coefficient. For such materials, the wave velocities in the

Figure 13.19 Working principle of a MEMS SAW gyroscope