Page 399 - Microsensors, MEMS and Smart Devices - Gardner Varadhan and Awadelkarim

P. 399

APPLICATIONS 379

in humidity. Therefore, the uncoated side is used for measuring the temperature, which is

then used to compensate for temperature changes in the humidity measurement from the

coated side. There are up to three phase shifters (not shown) in front of each reflector.

The unique arrangement of these phase shifters gives the sensors their unique identifica-

tion number, which can also be determined by the wireless system based on the reflected

electromagnetic signal. The bus is connected to the two terminals of each IDT and this

is inductively coupled with the sensor antenna through an air gap.

The SiO2 coating used on the wireless humidity sensor is 40 to 50 nm thick and was

deposited using plasma-enhanced chemical vapour deposition (PECVD). A glass mask

was prepared to deposit the film only on the area indicated in Figure 13.17. The coating

is amorphous and porous to give it a high sensitivity to water vapour.

In order to protect the IDTs and reflectors, they should be coated with a very thin

(about 1 um) layer of a passivation layer that is not affected by moisture. One candidate

is amorphous silicon nitride (SiN xH y). SiN xH y has excellent passivation properties, which

make it ideal for use in the semiconductor industry as an insulator and as a protective

layer for silicon devices. SiN xH y can be deposited from the reaction of silane (SiH4)

with either ammonia (NH 3) or nitrogen (N2). Using plasma to assist in the deposition,

these films are deposited at much lower temperatures than by any other techniques (about

350 °C instead of more than 750 °C).

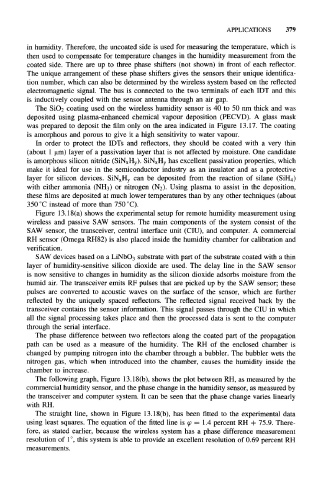

Figure 13.18(a) shows the experimental setup for remote humidity measurement using

wireless and passive SAW sensors. The main components of the system consist of the

SAW sensor, the transceiver, central interface unit (CIU), and computer. A commercial

RH sensor (Omega RH82) is also placed inside the humidity chamber for calibration and

verification.

SAW devices based on a LiNbO 3 substrate with part of the substrate coated with a thin

layer of humidity-sensitive silicon dioxide are used. The delay line in the SAW sensor

is now sensitive to changes in humidity as the silicon dioxide adsorbs moisture from the

humid air. The transceiver emits RF pulses that are picked up by the SAW sensor; these

pulses are converted to acoustic waves on the surface of the sensor, which are further

reflected by the uniquely spaced reflectors. The reflected signal received back by the

transceiver contains the sensor information. This signal passes through the CIU in which

all the signal processing takes place and then the processed data is sent to the computer

through the serial interface.

The phase difference between two reflectors along the coated part of the propagation

path can be used as a measure of the humidity. The RH of the enclosed chamber is

changed by pumping nitrogen into the chamber through a bubbler. The bubbler wets the

nitrogen gas, which when introduced into the chamber, causes the humidity inside the

chamber to increase.

The following graph, Figure 13.18(b), shows the plot between RH, as measured by the

commercial humidity sensor, and the phase change in the humidity sensor, as measured by

the transceiver and computer system. It can be seen that the phase change varies linearly

with RH.

The straight line, shown in Figure 13.18(b), has been fitted to the experimental data

using least squares. The equation of the fitted line is <p = 1.4 percent RH + 75.9. There-

fore, as stated earlier, because the wireless system has a phase difference measurement

resolution of 1°, this system is able to provide an excellent resolution of 0.69 percent RH

measurements.