Page 428 - Microsensors, MEMS and Smart Devices - Gardner Varadhan and Awadelkarim

P. 428

408 MEMS-IDT MICROSENSORS

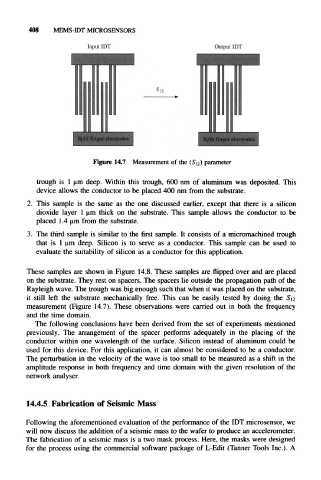

Figure 14.7 Measurement of the (Sj 2) parameter

trough is 1 \im deep. Within this trough, 600 nm of aluminum was deposited. This

device allows the conductor to be placed 400 nm from the substrate.

2. This sample is the same as the one discussed earlier, except that there is a silicon

dioxide layer 1 um thick on the substrate. This sample allows the conductor to be

placed 1.4 um from the substrate.

3. The third sample is similar to the first sample. It consists of a micromachined trough

that is 1 um deep. Silicon is to serve as a conductor. This sample can be used to

evaluate the suitability of silicon as a conductor for this application.

These samples are shown in Figure 14.8. These samples are flipped over and are placed

on the substrate. They rest on spacers. The spacers lie outside the propagation path of the

Rayleigh wave. The trough was big enough such that when it was placed on the substrate,

it still left the substrate mechanically free. This can be easily tested by doing the S\2

measurement (Figure 14.7). These observations were carried out in both the frequency

and the time domain.

The following conclusions have been derived from the set of experiments mentioned

previously. The arrangement of the spacer performs adequately in the placing of the

conductor within one wavelength of the surface. Silicon instead of aluminum could be

used for this device. For this application, it can almost be considered to be a conductor.

The perturbation in the velocity of the wave is too small to be measured as a shift in the

amplitude response in both frequency and time domain with the given resolution of the

network analyser.

14.4.5 Fabrication of Seismic Mass

Following the aforementioned evaluation of the performance of the IDT microsensor, we

will now discuss the addition of a seismic mass to the wafer to produce an accelerometer.

The fabrication of a seismic mass is a two mask process. Here, the masks were designed

for the process using the commercial software package of L-Edit (Tanner Tools Inc.). A