Page 81 - Microsensors, MEMS and Smart Devices - Gardner Varadhan and Awadelkarim

P. 81

62 STANDARD MICROELECTRONIC TECHNOLOGIES

Microelectronic technologies

Wafer fabrication Signal interconnect/packaging

Monolithic processing

Crystal Epitaxial Wafer Monolithic Printed circuit Hybrid

growth growth many

Bipolar MOS SOI

I

BiCMOS

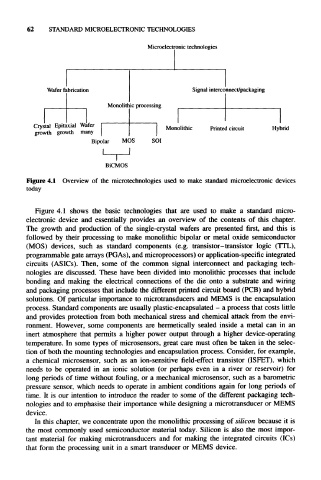

Figure 4.1 Overview of the microtechnologies used to make standard microelectronic devices

today

Figure 4.1 shows the basic technologies that are used to make a standard micro-

electronic device and essentially provides an overview of the contents of this chapter.

The growth and production of the single-crystal wafers are presented first, and this is

followed by their processing to make monolithic bipolar or metal oxide semiconductor

(MOS) devices, such as standard components (e.g. transistor—transistor logic (TTL),

programmable gate arrays (PGAs), and microprocessors) or application-specific integrated

circuits (ASICs). Then, some of the common signal interconnect and packaging tech

nologies are discussed. These have been divided into monolithic processes that include

bonding and making the electrical connections of the die onto a substrate and wiring

and packaging processes that include the different printed circuit board (PCB) and hybrid

solutions. Of particular importance to microtransducers and MEMS is the encapsulation

process. Standard components are usually plastic-encapsulated - a process that costs little

and provides protection from both mechanical stress and chemical attack from the envi-

ronment. However, some components are hermetically sealed inside a metal can in an

inert atmosphere that permits a higher power output through a higher device-operating

temperature. In some types of microsensors, great care must often be taken in the selec-

tion of both the mounting technologies and encapsulation process. Consider, for example,

a chemical microsensor, such as an ion-sensitive field-effect transistor (ISFET), which

needs to be operated in an ionic solution (or perhaps even in a river or reservoir) for

long periods of time without fouling, or a mechanical microsensor, such as a barometric

pressure sensor, which needs to operate in ambient conditions again for long periods of

time. It is our intention to introduce the reader to some of the different packaging tech-

nologies and to emphasise their importance while designing a microtransducer or MEMS

device.

In this chapter, we concentrate upon the monolithic processing of silicon because it is

the most commonly used semiconductor material today. Silicon is also the most impor-

tant material for making microtransducers and for making the integrated circuits (ICs)

that form the processing unit in a smart transducer or MEMS device.