Page 83 - Microsensors, MEMS and Smart Devices - Gardner Varadhan and Awadelkarim

P. 83

64 STANDARD MICROELECTRONIC TECHNOLOGIES

Reaction chamber

Silicon bridge

Slim rod, 4 mm diameter

Polycrystalline

silicon rod

Quartz bell

Graphite holder

Insulation

Power input

SiHCl 3 + H 2

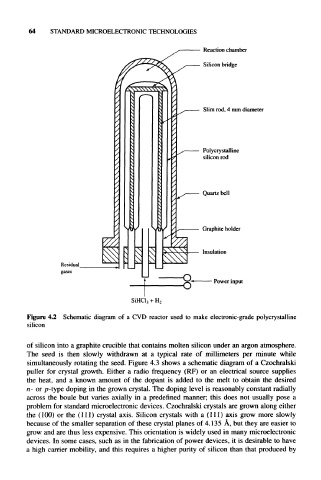

Figure 4.2 Schematic diagram of a CVD reactor used to make electronic-grade polycrystalline

silicon

of silicon into a graphite crucible that contains molten silicon under an argon atmosphere.

The seed is then slowly withdrawn at a typical rate of millimeters per minute while

simultaneously rotating the seed. Figure 4.3 shows a schematic diagram of a Czochralski

puller for crystal growth. Either a radio frequency (RF) or an electrical source supplies

the heat, and a known amount of the dopant is added to the melt to obtain the desired

n- or P-type doping in the grown crystal. The doping level is reasonably constant radially

across the boule but varies axially in a predefined manner; this does not usually pose a

problem for standard microelectronic devices. Czochralski crystals are grown along either

the (100) or the (111) crystal axis. Silicon crystals with a (111) axis grow more slowly

because of the smaller separation of these crystal planes of 4.135 A, but they are easier to

grow and are thus less expensive. This orientation is widely used in many microelectronic

devices. In some cases, such as in the fabrication of power devices, it is desirable to have

a high carrier mobility, and this requires a higher purity of silicon than that produced by