Page 87 - Microsensors, MEMS and Smart Devices - Gardner Varadhan and Awadelkarim

P. 87

68 STANDARD MICROELECTRONIC TECHNOLOGIES

4.2.3 Epitaxial Deposition

Epitaxial deposition is a process in which a thin, single-crystal layer can be deposited onto

the surface of a substrate wafer. The substrate wafer acts as a seeding layer and usually

has the same crystal structure as that of the epitaxial layer. Epitaxial growth is now

increasingly used in the production of both discrete devices and ICs. It is most commonly

used to isolate junctions from the substrate, that is, in junction isolation (JI) technology and

to allow formation of buried layers. JI technology permits the fabrication of circuits with

better characteristics, such as lower parasitic capacitances and faster switching speeds.

The most common types of epitaxial deposition are vapour-phase epitaxy (VPE) and

molecular beam epitaxy (MBE).

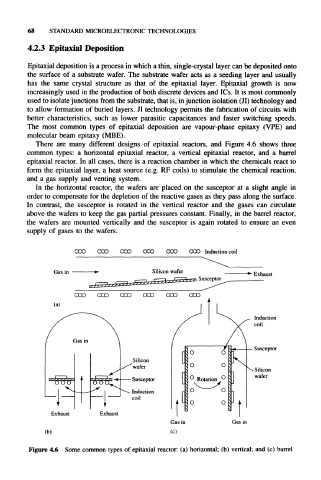

There are many different designs of epitaxial reactors, and Figure 4.6 shows three

common types: a horizontal epitaxial reactor, a vertical epitaxial reactor, and a barrel

epitaxial reactor. In all cases, there is a reaction chamber in which the chemicals react to

form the epitaxial layer, a heat source (e.g. RF coils) to stimulate the chemical reaction,

and a gas supply and venting system.

In the horizontal reactor, the wafers are placed on the susceptor at a slight angle in

order to compensate for the depletion of the reactive gases as they pass along the surface.

In contrast, the susceptor is rotated in the vertical reactor and the gases can circulate

above the wafers to keep the gas partial pressures constant. Finally, in the barrel reactor,

the wafers are mounted vertically and the susceptor is again rotated to ensure an even

supply of gases to the wafers.

OCX) Induction coil

Gas in Exhaust

(a)

Gas in

Susceptor

Silicon [

wafer

Silicon

Susceptor [ Rotation ] wafer

Induction

coil

O O

Exhaust Exhaust

Gas in Gas in

(b) (c)

Figure 4.6 Some common types of epitaxial reactor: (a) horizontal; (b) vertical; and (c) barrel