Page 86 - Microsensors, MEMS and Smart Devices - Gardner Varadhan and Awadelkarim

P. 86

WAFER PREPARATION 67

First, the boule is ground down to a standard diameter for use in the automated processing

of wafers. This is done by a variety of wheel or belt grinders with a bias of about

+0.4 mm, but it leaves a damaged surface on the crystal. The outer damaged material

is then removed later by a less harsh treatment to give the desired wafer diameter (see

following text). The standard wafer sizes vary according to the microelectronic compo-

nent that is manufactured and the desired yield. Low volume production (e.g. specialist

microsensors/MEMS fabrication) may still use a 3" 4" or 6" wafer, whereas high volume

production of memory or microprocessor chips would use the highest available diameter,

that is, 8" or higher.

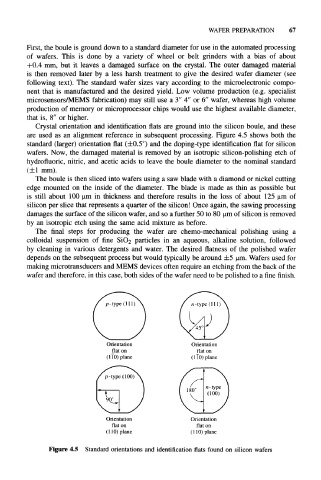

Crystal orientation and identification flats are ground into the silicon boule, and these

are used as an alignment reference in subsequent processing. Figure 4.5 shows both the

standard (larger) orientation flat (±0.5°) and the doping-type identification flat for silicon

wafers. Now, the damaged material is removed by an isotropic silicon-polishing etch of

hydrofluoric, nitric, and acetic acids to leave the boule diameter to the nominal standard

(±1 mm).

The boule is then sliced into wafers using a saw blade with a diamond or nickel cutting

edge mounted on the inside of the diameter. The blade is made as thin as possible but

is still about 100 um in thickness and therefore results in the loss of about 125 urn of

silicon per slice that represents a quarter of the silicon! Once again, the sawing processing

damages the surface of the silicon wafer, and so a further 50 to 80 um of silicon is removed

by an isotropic etch using the same acid mixture as before.

The final steps for producing the wafer are chemo-mechanical polishing using a

colloidal suspension of fine SiO 2 particles in an aqueous, alkaline solution, followed

by cleaning in various detergents and water. The desired flatness of the polished wafer

depends on the subsequent process but would typically be around ±5 urn. Wafers used for

making microtransducers and MEMS devices often require an etching from the back of the

wafer and therefore, in this case, both sides of the wafer need to be polished to a fine finish.

Orientation Orientation

flat on flat on

(110) plane (110) plane

Orientation Orientation

flat on flat on

(110) plane (110) plane

Figure 4.5 Standard orientations and identification flats found on silicon wafers