Page 76 - Microsensors, MEMS and Smart Devices - Gardner Varadhan and Awadelkarim

P. 76

SEMICONDUCTORS 57

Table 3.7 A list of specifications for silicon wafers

Diameter Parameter 100 mm 125 mm 150 mm

Thickness (mm) 0.50-0.55 0.60-0.65 0.65-0.70

Primary flat a 30-35 40-45 55-60

length (mm)

Secondary flat 16-20 25-30 35-40

length (mm)

Bow (mm) 70 60

Total thickness 65 50

variation (u,m)

Surface orientation (100) or (111) (100) or (111) (100) or (111)

"Wafer flats are defined in Section 4.2.

from crystal growth from the melt in that the epitaxial layer can be grown at a temperature

very much below the melting point. Among various epitaxial processes, vapour-phase

epitaxy (VPE) is the usual process for silicon layer growth.

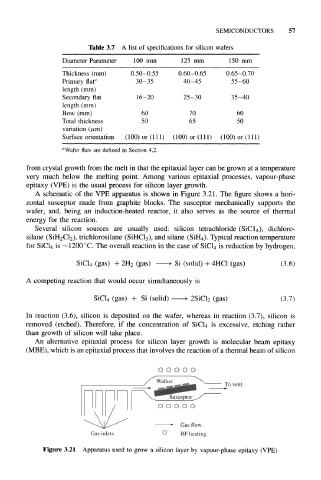

A schematic of the VPE apparatus is shown in Figure 3.21. The figure shows a hori-

zontal susceptor made from graphite blocks. The susceptor mechanically supports the

wafer, and, being an induction-heated reactor, it also serves as the source of thermal

energy for the reaction.

Several silicon sources are usually used: silicon tetrachloride (SiCl 4), dichloro-

silane (SiH 2Cl 2), trichlorosilane (SiHCl 3), and silane (SiH 4). Typical reaction temperature

for SiCl 4 is ~1200°C. The overall reaction in the case of SiCl 4 is reduction by hydrogen,

SiCl 4 (gas) + 2H 2 (gas) > Si (solid) + 4HC1 (gas) (3.6)

A competing reaction that would occur simultaneously is

(gas) + Si (solid) 2SiCl 2 (gas) (3.7)

SiCl 4

In reaction (3.6), silicon is deposited on the wafer, whereas in reaction (3.7), silicon is

removed (etched). Therefore, if the concentration of SiCl 4 is excessive, etching rather

than growth of silicon will take place.

An alternative epitaxial process for silicon layer growth is molecular beam epitaxy

(MBE), which is an epitaxial process that involves the reaction of a thermal beam of silicon

To vent

Gas flow

Gas inlets O RF heating

Figure 3.21 Apparatus used to grow a silicon layer by vapour-phase epitaxy (VPE)