Page 74 - Microsensors, MEMS and Smart Devices - Gardner Varadhan and Awadelkarim

P. 74

SEMICONDUCTORS 55

in a furnace with different carbon-releasing materials such as coal and coke. Several

reactions take place inside the furnace and the net reaction that results in silicon is

SiC + SiO 2 Si + SiO (gas) + CO (gas) (3.3)

The silicon so produced is called metallurgical-grade silicon (MGS), which contains up

to 2 percent impurities. Subsequently, the silicon is treated with hydrogen chloride (HC1)

to form trichlorosilane (SiHCl 3):

Si + 3HC1 SiHCl 3 (gas) + H 2 (gas) (3.4)

is liquid at room temperature. Fractional distillation of the SiHCl 3 liquid removes

impurities, and the purified liquid is reduced in a hydrogen atmosphere to yield electronic-

grade silicon (EGS) through the reaction

SiHCl 3 + H Si + 3HC1 (3.5)

EGS is a polycrystalline material of remarkably high purity and is used as the raw material

for preparing high-quality silicon wafers.

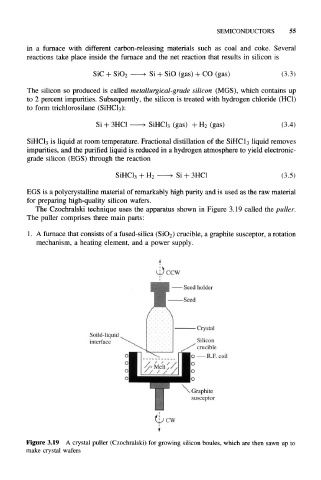

The Czochralski technique uses the apparatus shown in Figure 3.19 called the puller.

The puller comprises three main parts:

1. A furnace that consists of a fused-silica (SiO 2) crucible, a graphite susceptor, a rotation

mechanism, a heating element, and a power supply.

CCW

Seed holder

Seed

Soild-liquid

interface

Graphite

susceptor

Figure 3.19 A crystal puller (Czochralski) for growing silicon boules, which are then sawn up to

make crystal wafers