Page 70 - Microsensors, MEMS and Smart Devices - Gardner Varadhan and Awadelkarim

P. 70

METALS 51

Vacuum

enclosure

Sample

Molten

evaporated Shutter

material

Heated crucible

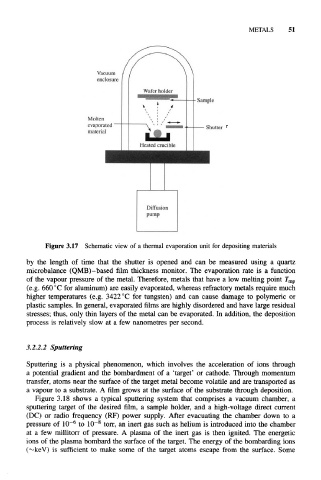

Figure 3.17 Schematic view of a thermal evaporation unit for depositing materials

by the length of time that the shutter is opened and can be measured using a quartz

microbalance (QMB)—based film thickness monitor. The evaporation rate is a function

of the vapour pressure of the metal. Therefore, metals that have a low melting point T mp

(e.g. 660 °C for aluminum) are easily evaporated, whereas refractory metals require much

higher temperatures (e.g. 3422 °C for tungsten) and can cause damage to polymeric or

plastic samples. In general, evaporated films are highly disordered and have large residual

stresses; thus, only thin layers of the metal can be evaporated. In addition, the deposition

process is relatively slow at a few nanometres per second.

3.2.2.2 Sputtering

Sputtering is a physical phenomenon, which involves the acceleration of ions through

a potential gradient and the bombardment of a 'target' or cathode. Through momentum

transfer, atoms near the surface of the target metal become volatile and are transported as

a vapour to a substrate. A film grows at the surface of the substrate through deposition.

Figure 3.18 shows a typical sputtering system that comprises a vacuum chamber, a

sputtering target of the desired film, a sample holder, and a high-voltage direct current

(DC) or radio frequency (RF) power supply. After evacuating the chamber down to a

pressure of 10 –6 to 10 –8 torr, an inert gas such as helium is introduced into the chamber

at a few millitorr of pressure. A plasma of the inert gas is then ignited. The energetic

ions of the plasma bombard the surface of the target. The energy of the bombarding ions

(~keV) is sufficient to make some of the target atoms escape from the surface. Some