Page 24 - Modeling of Chemical Kinetics and Reactor Design

P. 24

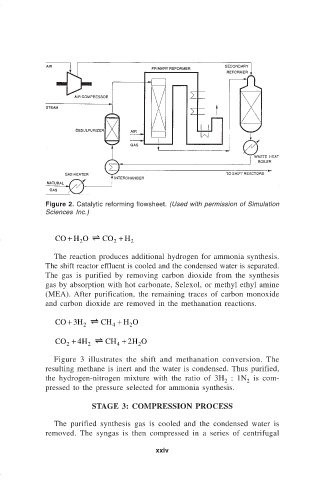

Figure 2. Catalytic reforming flowsheet. (Used with permission of Simulation

Sciences Inc.)

CO H O [

+ 2 CO + H 2

2

The reaction produces additional hydrogen for ammonia synthesis.

The shift reactor effluent is cooled and the condensed water is separated.

The gas is purified by removing carbon dioxide from the synthesis

gas by absorption with hot carbonate, Selexol, or methyl ethyl amine

(MEA). After purification, the remaining traces of carbon monoxide

and carbon dioxide are removed in the methanation reactions.

CO + 3

H [ CH + H O

4

2

2

CO +

2 4 H [ CH + 2 H O

2

4

2

Figure 3 illustrates the shift and methanation conversion. The

resulting methane is inert and the water is condensed. Thus purified,

the hydrogen-nitrogen mixture with the ratio of 3H : 1N is com-

2 2

pressed to the pressure selected for ammonia synthesis.

STAGE 3: COMPRESSION PROCESS

The purified synthesis gas is cooled and the condensed water is

removed. The syngas is then compressed in a series of centrifugal

xxiv