Page 28 - Modeling of Chemical Kinetics and Reactor Design

P. 28

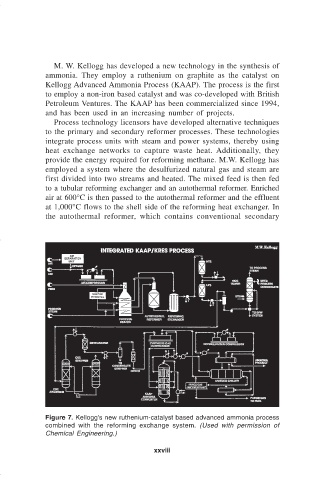

M. W. Kellogg has developed a new technology in the synthesis of

ammonia. They employ a ruthenium on graphite as the catalyst on

Kellogg Advanced Ammonia Process (KAAP). The process is the first

to employ a non-iron based catalyst and was co-developed with British

Petroleum Ventures. The KAAP has been commercialized since 1994,

and has been used in an increasing number of projects.

Process technology licensors have developed alternative techniques

to the primary and secondary reformer processes. These technologies

integrate process units with steam and power systems, thereby using

heat exchange networks to capture waste heat. Additionally, they

provide the energy required for reforming methane. M.W. Kellogg has

employed a system where the desulfurized natural gas and steam are

first divided into two streams and heated. The mixed feed is then fed

to a tubular reforming exchanger and an autothermal reformer. Enriched

air at 600°C is then passed to the autothermal reformer and the effluent

at 1,000°C flows to the shell side of the reforming heat exchanger. In

the autothermal reformer, which contains conventional secondary

Figure 7. Kellogg’s new ruthenium-catalyst based advanced ammonia process

combined with the reforming exchange system. (Used with permission of

Chemical Engineering.)

xxviii