Page 25 - Modeling of Chemical Kinetics and Reactor Design

P. 25

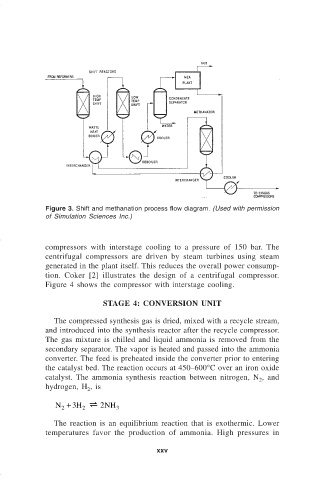

Figure 3. Shift and methanation process flow diagram. (Used with permission

of Simulation Sciences Inc.)

compressors with interstage cooling to a pressure of 150 bar. The

centrifugal compressors are driven by steam turbines using steam

generated in the plant itself. This reduces the overall power consump-

tion. Coker [2] illustrates the design of a centrifugal compressor.

Figure 4 shows the compressor with interstage cooling.

STAGE 4: CONVERSION UNIT

The compressed synthesis gas is dried, mixed with a recycle stream,

and introduced into the synthesis reactor after the recycle compressor.

The gas mixture is chilled and liquid ammonia is removed from the

secondary separator. The vapor is heated and passed into the ammonia

converter. The feed is preheated inside the converter prior to entering

the catalyst bed. The reaction occurs at 450–600°C over an iron oxide

catalyst. The ammonia synthesis reaction between nitrogen, N , and

2

hydrogen, H , is

2

N + 3 H [ 2 NH

2 2 3

The reaction is an equilibrium reaction that is exothermic. Lower

temperatures favor the production of ammonia. High pressures in

xxv