Page 197 - Modular design for machine tools

P. 197

Application of Machine Tool Description to Engineering Design 157

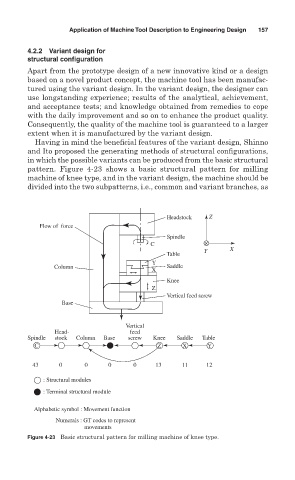

4.2.2 Variant design for

structural configuration

Apart from the prototype design of a new innovative kind or a design

based on a novel product concept, the machine tool has been manufac-

tured using the variant design. In the variant design, the designer can

use longstanding experience; results of the analytical, achievement,

and acceptance tests; and knowledge obtained from remedies to cope

with the daily improvement and so on to enhance the product quality.

Consequently, the quality of the machine tool is guaranteed to a larger

extent when it is manufactured by the variant design.

Having in mind the beneficial features of the variant design, Shinno

and Ito proposed the generating methods of structural configurations,

in which the possible variants can be produced from the basic structural

pattern. Figure 4-23 shows a basic structural pattern for milling

machine of knee type, and in the variant design, the machine should be

divided into the two subpatterns, i.e., common and variant branches, as

Headstock Z

Flow of force

Spindle

C

X

Y

Table

Y

Column Saddle

X

Knee

Z

Vertical feed screw

Base

Vertical

Head- feed

Spindle stock Column Base screw Knee Saddle Table

C Z X Y

43 0 0 0 0 13 11 12

: Structural modules

: Terminal structural module

Alphabetic symbol : Movement function

Numerals : GT codes to represent

movements

Figure 4-23 Basic structural pattern for milling machine of knee type.