Page 220 - Modular design for machine tools

P. 220

180 Engineering Design for Machine Tool Joints

Stationary joint

between spindlehead

body and quill

Taper connection

Taper

connection

with tool

shank

Press-fitted joint

of stepped sleeve Stationary joint Rolling joint between

between outer race roller and race

of bearing and quill

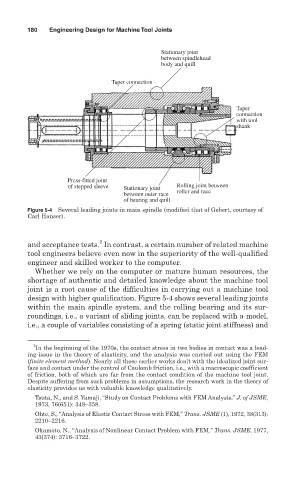

Figure 5-4 Several leading joints in main spindle (modified that of Gebert, courtesy of

Carl Hanser).

2

and acceptance tests. In contrast, a certain number of related machine

tool engineers believe even now in the superiority of the well-qualified

engineer and skilled worker to the computer.

Whether we rely on the computer or mature human resources, the

shortage of authentic and detailed knowledge about the machine tool

joint is a root cause of the difficulties in carrying out a machine tool

design with higher qualification. Figure 5-4 shows several leading joints

within the main spindle system, and the rolling bearing and its sur-

roundings, i.e., a variant of sliding joints, can be replaced with a model,

i.e., a couple of variables consisting of a spring (static joint stiffness) and

2

In the beginning of the 1970s, the contact stress in two bodies in contact was a lead-

ing issue in the theory of elasticity, and the analysis was carried out using the FEM

(finite element method). Nearly all those earlier works dealt with the idealized joint sur-

face and contact under the control of Coulomb friction, i.e., with a macroscopic coefficient

of friction, both of which are far from the contact condition of the machine tool joint.

Despite suffering from such problems in assumptions, the research work in the theory of

elasticity provides us with valuable knowledge qualitatively.

Tsuta, N., and S. Yamaji, “Study on Contact Problems with FEM Analysis,” J. of JSME,

1973, 76(651): 348–358.

Ohte, S., “Analysis of Elastic Contact Stress with FEM,” Trans. JSME (1), 1972, 38(313):

2210–2216.

Okamoto, N., “Analysis of Nonlinear Contact Problem with FEM,” Trans. JSME, 1977,

43(374): 3716–3722.