Page 223 - Modular design for machine tools

P. 223

Basic Knowledge of Machine Tool Joints 183

Column Column

Guide key

Connecting Taper pin

bolt

Base

Base

(a) (b)

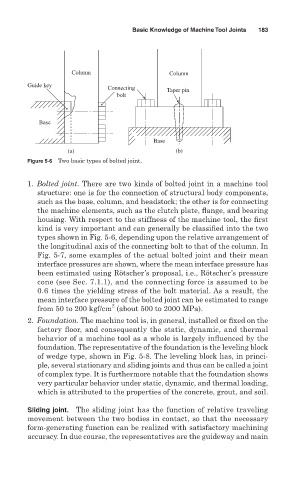

Figure 5-6 Two basic types of bolted joint.

1. Bolted joint. There are two kinds of bolted joint in a machine tool

structure: one is for the connection of structural body components,

such as the base, column, and headstock; the other is for connecting

the machine elements, such as the clutch plate, flange, and bearing

housing. With respect to the stiffness of the machine tool, the first

kind is very important and can generally be classified into the two

types shown in Fig. 5-6, depending upon the relative arrangement of

the longitudinal axis of the connecting bolt to that of the column. In

Fig. 5-7, some examples of the actual bolted joint and their mean

interface pressures are shown, where the mean interface pressure has

been estimated using Rötscher’s proposal, i.e., Rötscher’s pressure

cone (see Sec. 7.1.1), and the connecting force is assumed to be

0.6 times the yielding stress of the bolt material. As a result, the

mean interface pressure of the bolted joint can be estimated to range

2

from 50 to 200 kgf/cm (about 500 to 2000 MPa).

2. Foundation. The machine tool is, in general, installed or fixed on the

factory floor, and consequently the static, dynamic, and thermal

behavior of a machine tool as a whole is largely influenced by the

foundation. The representative of the foundation is the leveling block

of wedge type, shown in Fig. 5-8. The leveling block has, in princi-

ple, several stationary and sliding joints and thus can be called a joint

of complex type. It is furthermore notable that the foundation shows

very particular behavior under static, dynamic, and thermal loading,

which is attributed to the properties of the concrete, grout, and soil.

Sliding joint. The sliding joint has the function of relative traveling

movement between the two bodies in contact, so that the necessary

form-generating function can be realized with satisfactory machining

accuracy. In due course, the representatives are the guideway and main