Page 224 - Modular design for machine tools

P. 224

184 Engineering Design for Machine Tool Joints

8-f33 40 250 440 250 250 350 40

2-f25 55 55 50 60

160 200 160 490 M26

160 160 605 M30 50 1620 70

95 10-f28 68

185 1035 185 45

1405 (ii) Double column type planer

(i) Double column type planomiller (Billeter A.G., width of table 2500 mm)

(Kollman A.G., width of table 1500 mm)

40 60

40 400 400 400 40 55

300 680

300 M30

1280 40

8-f32

(iii) Double column type planer

(Kinoshita Co. Ltd., width of table 1400 mm)

(a)

Mean interface pressure p, kgf/mm 2

Material of connecting bolt

S45C (JIS) S45C (JIS)

SS41B (JIS) 10 k (DIN)

Normalizing Tempering

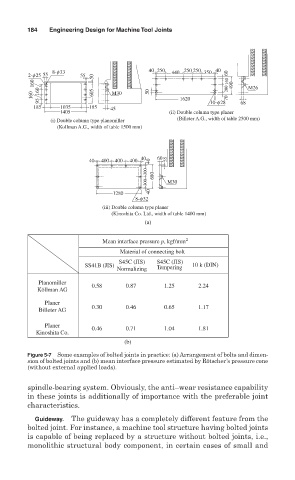

Planomiller 0.58 0.87 1.25 2.24

Köllman AG

Planer

Billeter AG 0.30 0.46 0.65 1.17

Planer

0.46 0.71 1.04 1.81

Kinoshita Co.

(b)

Figure 5-7 Some examples of bolted joints in practice: (a) Arrangement of bolts and dimen-

sion of bolted joints and (b) mean interface pressure estimated by Rötscher’s pressure cone

(without external applied loads).

spindle-bearing system. Obviously, the anti–wear resistance capability

in these joints is additionally of importance with the preferable joint

characteristics.

Guideway. The guideway has a completely different feature from the

bolted joint. For instance, a machine tool structure having bolted joints

is capable of being replaced by a structure without bolted joints, i.e.,

monolithic structural body component, in certain cases of small and