Page 222 - Modular design for machine tools

P. 222

182 Engineering Design for Machine Tool Joints

joint, in addition to its apparent features and structural configuration,

the following technological aspects should be taken into consideration:

in what way and how much the joint to be considered affects the over-

all behavior of the machine tool. In classifying the joint, moreover, the

joint in a machine-tool-work system, e.g., the joint between the cutting

tool and the work should be incorporated.

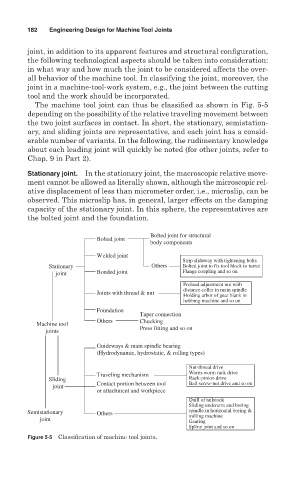

The machine tool joint can thus be classified as shown in Fig. 5-5

depending on the possibility of the relative traveling movement between

the two joint surfaces in contact. In short, the stationary, semistation-

ary, and sliding joints are representative, and each joint has a consid-

erable number of variants. In the following, the rudimentary knowledge

about each leading joint will quickly be noted (for other joints, refer to

Chap. 9 in Part 2).

Stationary joint. In the stationary joint, the macroscopic relative move-

ment cannot be allowed as literally shown, although the microscopic rel-

ative displacement of less than micrometer order, i.e., microslip, can be

observed. This microslip has, in general, larger effects on the damping

capacity of the stationary joint. In this sphere, the representatives are

the bolted joint and the foundation.

Bolted joint for structural

Bolted joint

body components

Welded joint

Strip slideway with tightening bolts

Stationary Others Bolted joint to fix tool block to turret

joint Bonded joint Flange coupling and so on

Preload adjustment nut with

distance collar in main spindle

Joints with thread & nut

Holding arbor of gear blank in

hobbing machine and so on

Foundation

Taper connection

Others Chucking

Machine tool

joints Press fitting and so on

Guideways & main spindle bearing

(Hydrodynamic, hydrostatic, & rolling types)

Nut-thread drive

Worm-worm rack drive

Traveling mechanism

Sliding Rack-pinion drive

joint Contact portion between tool Ball screw-nut drive and so on

or attachment and workpiece

Quill of tailstock

Sliding underarm and boring

Semistationary Others spindle in horizontal boring &

joint milling machine

Gearing

Spline joint and so on

Figure 5-5 Classification of machine tool joints.