Page 229 - Modular design for machine tools

P. 229

Basic Knowledge of Machine Tool Joints 189

main spindle and can thus render the bearing nut useless to minimize

the unbalance. In short, the spindle-bearing system is one of the com-

plex joints, as is the foundation.

Semistationary joint. This joint can be regarded as a variant of the sta-

tionary or sliding joint, and a typical example is a slideway with a

clamping mechanism. The slideway behaves like the stationary joint or

sliding joint depending on whether the clamping mechanism is in work-

ing condition or not.

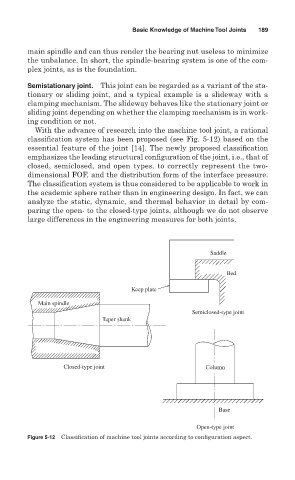

With the advance of research into the machine tool joint, a rational

classification system has been proposed (see Fig. 5-12) based on the

essential feature of the joint [14]. The newly proposed classification

emphasizes the leading structural configuration of the joint, i.e., that of

closed, semiclosed, and open types, to correctly represent the two-

dimensional FOF, and the distribution form of the interface pressure.

The classification system is thus considered to be applicable to work in

the academic sphere rather than in engineering design. In fact, we can

analyze the static, dynamic, and thermal behavior in detail by com-

paring the open- to the closed-type joints, although we do not observe

large differences in the engineering measures for both joints.

Saddle

Bed

Keep plate

Main spindle

Semiclosed-type joint

Taper shank

Closed-type joint Column

Base

Open-type joint

Figure 5-12 Classification of machine tool joints according to configuration aspect.