Page 266 - Book Hosokawa Nanoparticle Technology Handbook

P. 266

4.5 STRUCTURE CONTROL OF NANOPARTICLE COLLECTIVES BY SINTERING AND BONDING FUNDAMENTALS

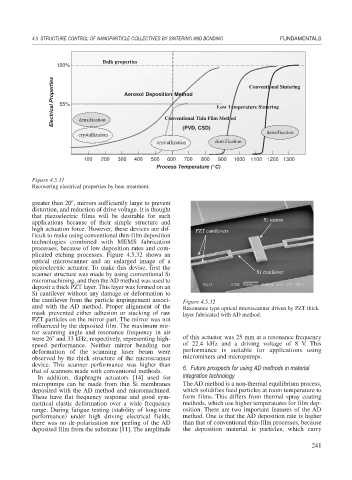

Bulk properties

100%

Electrical Properties 55% Aerosol Deposition Method Low Temperature Sintering

Conventional Sintering

Conventional Thin Film Method

densification

(PVD, CSD)

densification

crystallization

crystallization densification

100 200 300 400 500 600 700 800 900 1000 1100 1200 1300

Process Temperature (°C)

Figure 4.5.31

Recovering electrical properties by heat treatment.

greater than 20 , mirrors sufficiently large to prevent

distortion, and reduction of drive voltage. It is thought

that piezoelectric films will be desirable for such

applications because of their simple structure and Si mirror

high actuation force. However, these devices are dif- PZT cantilevers

ficult to make using conventional thin-film deposition

technologies combined with MEMS fabrication

processes, because of low deposition rates and com-

plicated etching processes. Figure 4.5.32 shows an

optical microscanner and an enlarged image of a

piezoelectric actuator. To make this devise, first the

scanner structure was made by using conventional Si Si cantilever

micromachining, and then the AD method was used to

deposit a thick PZT layer. This layer was formed on an

Si cantilever without any damage or deformation to

the cantilever from the particle impingement associ- Figure 4.5.32

ated with the AD method. Proper alignment of the Resonance type optical microscanner driven by PZT thick

mask prevented either adhesion or stacking of raw layer fabricated with AD method.

PZT particles on the mirror part. The mirror was not

influenced by the deposited film. The maximum mir-

ror scanning angle and resonance frequency in air

were 26 and 33 kHz, respectively, representing high- of this actuator was 25 mm at a resonance frequency

speed performance. Neither mirror bending nor of 22.4 kHz and a driving voltage of 8 V. This

deformation of the scanning laser beam were performance is suitable for applications using

observed by the thick structure of the microscanner micromixers and micropumps.

device. This scanner performance was higher than 6. Future prospects for using AD methods in material

that of scanners made with conventional methods.

In addition, diaphragm actuators [14] used for integration technology

micropumps can be made from thin Si membranes The AD method is a non-thermal equilibrium process,

deposited with the AD method and micromachined. which solidifies feed particles at room temperature to

These have flat frequency response and good sym- form films. This differs from thermal spray coating

metrical elastic deformation over a wide frequency methods, which use higher temperatures for film dep-

range. During fatigue testing (stability of long-time osition. There are two important features of the AD

performance) under high driving electrical fields, method. One is that the AD deposition rate is higher

there was no de-polarization nor peeling of the AD than that of conventional thin-film processes, because

deposited film from the substrate [11]. The amplitude the deposition material is particles, which carry

241