Page 262 - Book Hosokawa Nanoparticle Technology Handbook

P. 262

4.5 STRUCTURE CONTROL OF NANOPARTICLE COLLECTIVES BY SINTERING AND BONDING FUNDAMENTALS

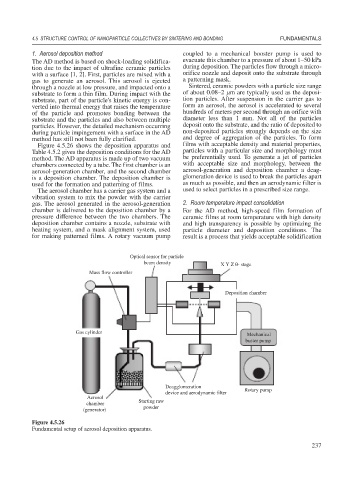

1. Aerosol deposition method coupled to a mechanical booster pump is used to

The AD method is based on shock-loading solidifica- evacuate this chamber to a pressure of about 1–50 kPa

tion due to the impact of ultrafine ceramic particles during deposition. The particles flow through a micro-

with a surface [1, 2]. First, particles are mixed with a orifice nozzle and deposit onto the substrate through

gas to generate an aerosol. This aerosol is ejected a patterning mask.

through a nozzle at low pressure, and impacted onto a Sintered, ceramic powders with a particle size range

substrate to form a thin film. During impact with the of about 0.08–2 m are typically used as the deposi-

substrate, part of the particle’s kinetic energy is con- tion particles. After suspension in the carrier gas to

verted into thermal energy that raises the temperature form an aerosol, the aerosol is accelerated to several

of the particle and promotes bonding between the hundreds of meters per second through an orifice with

substrate and the particles and also between multiple diameter less than 1 mm. Not all of the particles

particles. However, the detailed mechanism occurring deposit onto the substrate, and the ratio of deposited to

during particle impingement with a surface in the AD non-deposited particles strongly depends on the size

method has still not been fully clarified. and degree of aggregation of the particles. To form

Figure 4.5.26 shows the deposition apparatus and films with acceptable density and material properties,

Table 4.5.2 gives the deposition conditions for the AD particles with a particular size and morphology must

method. The AD apparatus is made up of two vacuum be preferentially used. To generate a jet of particles

chambers connected by a tube. The first chamber is an with acceptable size and morphology, between the

aerosol-generation chamber, and the second chamber aerosol-generation and deposition chamber a deag-

is a deposition chamber. The deposition chamber is glomeration device is used to break the particles apart

used for the formation and patterning of films. as much as possible, and then an aerodynamic filter is

The aerosol chamber has a carrier gas system and a used to select particles in a prescribed size range.

vibration system to mix the powder with the carrier

gas. The aerosol generated in the aerosol-generation 2. Room temperature impact consolidation

chamber is delivered to the deposition chamber by a For the AD method, high-speed film formation of

pressure difference between the two chambers. The ceramic films at room temperature with high density

deposition chamber contains a nozzle, substrate with and high transparency is possible by optimizing the

heating system, and a mask alignment system, used particle diameter and deposition conditions. The

for making patterned films. A rotary vacuum pump result is a process that yields acceptable solidification

Optical sensor for particle

beam density X Y Z θ- stage

Mass flow controller

Deposition chamber

Gas cylinder

Mechanical

buster pump

Deagglomeration

device and aerodynamic filter Rotary pump

Aerosol

chamber Starting raw

powder

(generator)

Figure 4.5.26

Fundamental setup of aerosol deposition apparatus.

237