Page 257 - Book Hosokawa Nanoparticle Technology Handbook

P. 257

FUNDAMENTALS CH. 4 CONTROL OF NANOSTRUCTURE OF MATERIALS

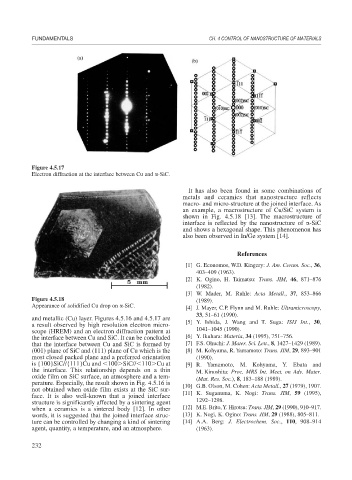

Figure 4.5.17

Electron diffraction at the interface between Cu and -SiC.

It has also been found in some combinations of

metals and ceramics that nanostructure reflects

macro- and micro-structure at the joined interface. As

an example, a macrostructure of Cu/SiC system is

shown in Fig. 4.5.18 [13]. The macrostructure of

interface is reflected by the nanostructure of -SiC

and shows a hexagonal shape. This phenomenon has

also been observed in In/Ge system [14].

References

[1] G. Economos, W.D. Kingery: J. Am. Ceram. Soc., 36,

403–409 (1963).

[2] K. Ogino, H. Taimatsu: Trans. JIM, 46, 871–876

(1982).

[3] W. Mader, M. Ruhle: Acta Metall., 37, 853–866

Figure 4.5.18 (1989).

Appearance of solidified Cu drop on -SiC. [4] J. Mayer, C.P. Flynn and M. Ruhle: Ultramicroscopy,

33, 51–61 (1990).

and metallic (Cu) layer. Figures 4.5.16 and 4.5.17 are [5] Y. Ishida, J. Wang and T. Suga: ISIJ Int., 30,

a result observed by high resolution electron micro-

scope (HREM) and an electron diffraction pattern at 1041–1045 (1990).

the interface between Cu and SiC. It can be concluded [6] Y. Ikuhara: Materia, 34 (1995), 751–756.

that the interface between Cu and SiC is formed by [7] F.S. Ohuchi: J. Mater. Sci. Lett., 8, 1427–1429 (1989).

(001) plane of SiC and (111) plane of Cu which is the [8] M. Kohyama, R. Yamamoto: Trans. JIM, 29, 893–901

most closed packed plane and a preferred orientation (1990).

is {100}SiC//{111}Cu and 100 SiC// 110 Cu at [9] R. Yamamoto, M. Kohyama, Y. Ebata and

the interface. This relationship depends on a thin M. Kinoshita: Proc. MRS Int. Meet. on Adv. Mater.

oxide film on SiC surface, an atmosphere and a tem- (Mat. Res. Soc.), 8, 183–188 (1989).

perature. Especially, the result shown in Fig. 4.5.16 is [10] G.B. Olson, M. Cohen: Acta Metall., 27 (1979), 1907.

not obtained when oxide film exists at the SiC sur- [11] K. Suganuma, K. Nogi: Trans. JIM, 59 (1995),

face. It is also well-known that a joined interface

structure is significantly affected by a sintering agent 1292–1298.

when a ceramics is a sintered body [12]. In other [12] M.E. Brito, Y. Hirotsu: Trans. JIM, 29 (1990), 910–917.

words, it is suggested that the joined interface struc- [13] K. Nogi, K. Ogino: Trans. JIM, 29 (1988), 805–811.

ture can be controlled by changing a kind of sintering [14] A.A. Berg: J. Electrochem. Soc., 110, 908–914

agent, quantity, a temperature, and an atmosphere. (1963).

232