Page 258 - Book Hosokawa Nanoparticle Technology Handbook

P. 258

4.5 STRUCTURE CONTROL OF NANOPARTICLE COLLECTIVES BY SINTERING AND BONDING FUNDAMENTALS

4.5.4 Joining by FSW Only the probe is forced into the material during weld-

ing, and the tool is moved along the interface. The

4.5.4.1 Friction stir welding material is restricted to the back plate. The joining is

Friction stir welding (FSW) has already entered the performed by plastic flow caused by the tool in the

practical use stage in various industrial fields such as solid state. Because the peak temperature does not

railroad vehicles, vessels, structures, and cars [1–5], reach the melting point and the material is in the solid

after it was developed by TWI (British Welding state at this time, the grains are refined, the decrease in

Institute) in 1991 [6, 7]. Research and development in the strength by welding is much lower than that of

this area has significantly increased in every country fusion welding, and, in some cases, the strength of the

around the world. In this joining method, as shown in joints is higher than that of the base metal. The details

Fig. 4.5.19(a), the columnar rotating tool at a high of the tool are to be referred to a textbook on FSW [8].

speed contacts the materials to produce frictional heat, A schematic diagram of the cross-sectional

and the materials can then be joined using the fric- microstructure of the welded part is shown in

tional heat. As shown in Fig. 4.5.19(b), the tool con- Fig. 4.5.20. The center, called the stir zone, consists of

sists of a large shoulder part and a probe part at the tip. a recrystallized microstructure which consists of

equiaxial grains of hundreds of nanometers to several

micrometers in diameters. Figure 4.5.21 [9] shows

(a) (b) ∅15

TEM images of the stir zones of pure aluminum and

pure Fe (IF steel). Outside the stir zone, there is the

Retreating Welding direction

Side thermo-mechanically affected zone (TMAZ), in which

the crystal grain was extended by plastic modification.

Outside the TMAZ, the heat affected zone (HAZ)

Sho ulder

Probe

exists, which is affected by the heat, but not affected

Advancing by the plastic deformation. As a reference, for the nor-

side M6

mal fusion welding, the grains grow from several tens

of microns to several hundreds of microns.

Figure 4.5.19 According to Frigaard et al. [10], the heat input dur-

Friction stir welding and tool (example for 5-mm thick plate).

ing FSW, Q(W), can be expressed as follows:

4

Q PNR 3 (4.5.1)

2

3

Base metal Stir zone

where is the friction coefficient, P the pressure

3

(N/m ), N the tool rotation speed (/s), and R the

shoulder diameter (m). For this equation, it is

HAZ TMAZ assumed that the heat is generated only between the

shoulder of the tool and the material. P is the load per

Figure 4.5.20 unit area of the shoulder part. Equation (4.5.1) can be

Schematic illustration of microstructure. used when the tool is not moved. When the tool is

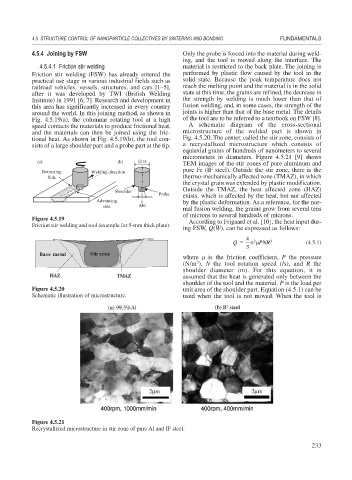

Figure 4.5.21

Recrystallized microstructure in stir zone of pure Al and IF steel.

233