Page 365 - Book Hosokawa Nanoparticle Technology Handbook

P. 365

6.3 THERMOPHYSICAL PROPERTIES FUNDAMENTALS

of a thickness less than 1 m. In order to solve this

problem, “A picosecond thermoreflectance method” to 1

observe change of the temperature of thin film front 50 nm

face by heat diffusion to the inside was developed [8].

The optical reflection intensity of the temperature

probe pulse is detected by photodiode. Since reflectiv- 100 nm

ity of material surface changes as a function of tem- Normalized temperature increase

perature, a change of specimen front-face temperature

is observed by a change of reflected light amplitude. 500 nm

This temperature measurement method with a temper-

ature change of such a reflectivity is called as ther- 0

moreflectance method. NMIJ/AIST of Japan developed

a thin film thermal diffusivity measurement system

based on a picosecond thermoreflectance method as 0 20 40 60 80

shown in Fig. 6.3.5. The laser beam emitted from a Delay time (ps)

mode-locked titanium sapphire laser is divided into

transmitted beam and reflected beam by a quartz plate Figure 6.3.6

and about 90% is used for pulse heating and about Thermoreflectance signals of three different thicknesses of

10% is used for temperature detection by thermore- aluminum thin films synthesized on glass substrates.

flectance method. Area of a diameter of several 10 m

of thin film face is heated by the picosecond laser

beam and the same position is irradiated by the probe limited by time duration of the light pulses. On the

beam. Then, the history of surface temperature is other hand, it is a weak point that sensibility of tem-

observed by the thermoreflectance method. perature detection is low.

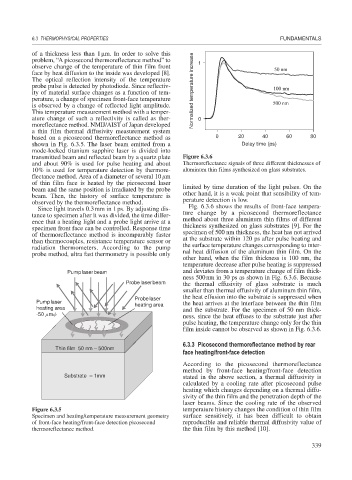

Since light travels 0.3mm in 1ps. By adjusting dis- Fig. 6.3.6 shows the results of front-face tempera-

tance to specimen after it was divided, the time differ- ture change by a picosecond thermoreflectance

ence that a heating light and a probe light arrive at a method about three aluminum thin films of different

specimen front face can be controlled. Response time thickness synthesized on glass substrates [9]. For the

of thermoreflectance method is incomparably faster specimen of 500 nm thickness, the heat has not arrived

than thermocouples, resistance temperature sensor or at the substrate within 120 ps after pulse heating and

radiation thermometers. According to the pump the surface temperature changes corresponding to inter-

probe method, ultra fast thermometry is possible only nal heat diffusion of the aluminum thin film. On the

other hand, when the film thickness is 100 nm, the

temperature decrease after pulse heating is suppressed

Pump laser beam and deviates from a temperature change of film thick-

ness 500nm in 30 ps as shown in Fig. 6.3.6. Because

Probe laser beam the thermal effusivity of glass substrate is much

smaller than thermal effusivity of aluminum thin film,

the heat effusion into the substrate is suppressed when

Probe laser

Pump laser heating area the heat arrives at the interface between the thin film

heating area and the substrate. For the specimen of 50 nm thick-

-50 m ness, since the heat effuses to the substrate just after

pulse heating, the temperature change only for the thin

film inside cannot be observed as shown in Fig. 6.3.6.

6.3.3 Picosecond thermoreflectance method by rear

Thin film 50 nm – 500nm

T h i n f i lm 5 0 n m – 5 00 nm

face heating/front-face detection

According to the picosecond thermoreflectance

method by front-face heating/front-face detection

Substrate – 1mm

Substrate – 1mm stated in the above section, a thermal diffusivity is

calculated by a cooling rate after picosecond pulse

heating which changes depending on a thermal diffu-

sivity of the thin film and the penetration depth of the

laser beams. Since the cooling rate of the observed

Figure 6.3.5 temperature history changes the condition of thin film

Specimen and heating/temperature measurement geometry surface sensitively, it has been difficult to obtain

of front-face heating/front-face detection picosecond reproducible and reliable thermal diffusivity value of

thermoreflectance method. the thin film by this method [10].

339