Page 368 - Book Hosokawa Nanoparticle Technology Handbook

P. 368

FUNDAMENTALS CH. 6 EVALUATION METHODS FOR PROPERTIES OF NANOSTRUCTURED BODY

PC

PC

Optical Fiber and

Collimation Head

Adjustable Mirror

Chopper Pump Pulsed Laser

Lens

Z Stage

Driver

Pulse

Specimen Holder Generator

Specimen

XYZ Stage

Lock-in Amplifier

Removable Mirror

Driver

Lens Beam Splitter

CCD Illuminator

Camera

Probe Pulsed Laser

Mirror Removable

Mirror

Lens

Differential

Photodiode Mirror

Motor Optical Fiber and

Collimation Head

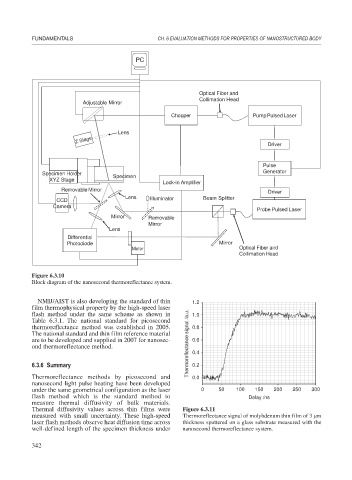

Figure 6.3.10

Block diagram of the nanosecond thermoreflectance system.

NMIJ/AIST is also developing the standard of thin 1.2

film thermophysical property by the high-speed laser

flash method under the same scheme as shown in 1.0

Table 6.3.1. The national standard for picosecond

thermoreflectance method was established in 2005. 0.8

The national standard and thin film reference material

are to be developed and supplied in 2007 for nanosec- Thermoreflectance signal /a.u. 0.6

ond thermoreflectance method. 0.4

6.3.6 Summary 0.2

Thermoreflectance methods by picosecond and 0.0

nanosecond light pulse heating have been developed

under the same geometrical configuration as the laser 0 50 100 150 200 250 300

flash method which is the standard method to Delay /ns

measure thermal diffusivity of bulk materials.

Thermal diffusivity values across thin films were Figure 6.3.11

measured with small uncertainty. These high-speed Thermoreflectance signal of molybdenum thin film of 3 m

laser flash methods observe heat diffusion time across thickness sputtered on a glass substrate measured with the

well-defined length of the specimen thickness under nanosecond thermoreflectance system.

342